Michelin fights against global warming and adapt to it

Fully aware of the severe impacts of global warming, the Group aligns its action with the 2015 Paris Climate Agreement on climate change, to make its activities compatible with a net zero emissions world by 2050. In response to this challenge, the Group focuses on energy transition and adaptation to climate risks.

Michelin decarbonization plan

As part of its climate change strategy, the Group has defined a decarbonization plan covering its direct and indirect activities*, i.e., all its production sites, its logistics operations, and its supply chain with raw material and component suppliers.

The main principles of Michelin's decarbonization plan and climate risk adaptation plan

Achieve net zero emissions by 2050, excluding usage phase, with a first step in CO2 emission reduction commitments in 2030.

Identify risks and necessary adaptations based on climate change scenarios. Identify acute and chronic climate risks and the necessary adaptation measures across the value chain, based on recognized climate change scenarios.

Communicate information transparently to the Company’s external stakeholders.

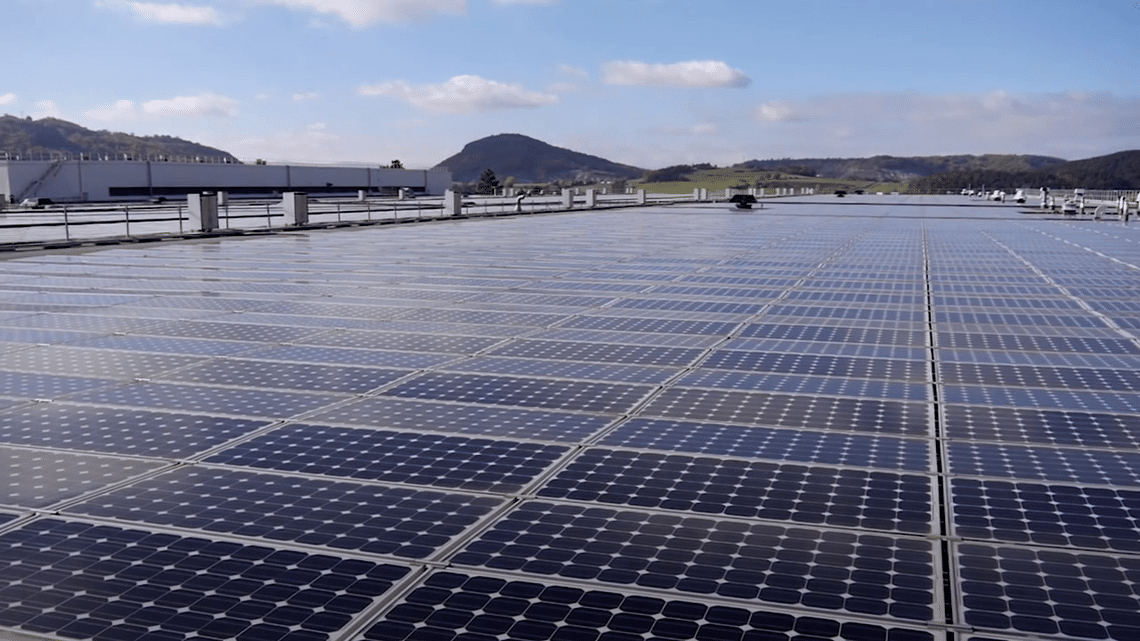

Towards energy sobriety

Products and services for low-carbon mobility

Design products with extremely high energy efficiency throughout their lifecycle, from the manufacturing process to their recycling, including the usage phase.

Develop services and solutions that optimize the use and management of vehicle fleets, reducing the consumption of fuel and other energy sources, and thus transport-related CO2 emissions.

Invest in new low-carbon mobility solutions, such as the development of the hydrogen industry, i.e., Symbio.

An international mobilization for the climate

The Group’s emissions reduction goals align with the 2015 Paris Climate Agreement. In July 2021, as part of the "Race to Zero - Business Ambition for 1.5°C" initiative, Michelin further strengthens the targets for its direct and indirect activities (Scopes 1, 2 and 3*), excluding the product use phase, so that they are compatible with net-zero emissions by 2050. The Group has formalized its commitment in line with the SBTI** Net Zero Standard through ambitious short- and long-term targets for the three scopes. With the “Race to Zero” commitment for all its direct and indirect activities, the Group is setting itself targets aligned with a 1.5°C warming scenario. *Scope 1 covers greenhouse gas (GHG) emissions emanating directly from the company (use of fossil fuels for its industrial processes, heating, etc.). Scope 2 accounts for indirect GHG emissions resulting from energy purchased and consumed by the company. Scope 3 covers all other indirect emissions, such as the purchase of raw materials and services, as well as the use of products and services sold. It is not the direct responsibility of the company. **The Science Based Targets initiative (SBTi) is a partnership between the CDP (formerly the Carbon Disclosure Project), the United Nations Global Compact, the World Resources Institute (WRI) and the WWF (previously named World Wide Fund). | |

Ambitions and results

Becoming a shareholder

Join an extraordinary human adventure that began more than 130 years ago with an innovative Group, leader in sustainable development.

Candidates

Do you want a chance to explore the full scope of your potential and contribute to human progress and a more sustainable world?