Designing and industrializing flexible composite products

The design of flexible composite products is part of the distinctive know-how that the Michelin Group can draw on to not only continue to grow in the tire business, but also expand into other areas.

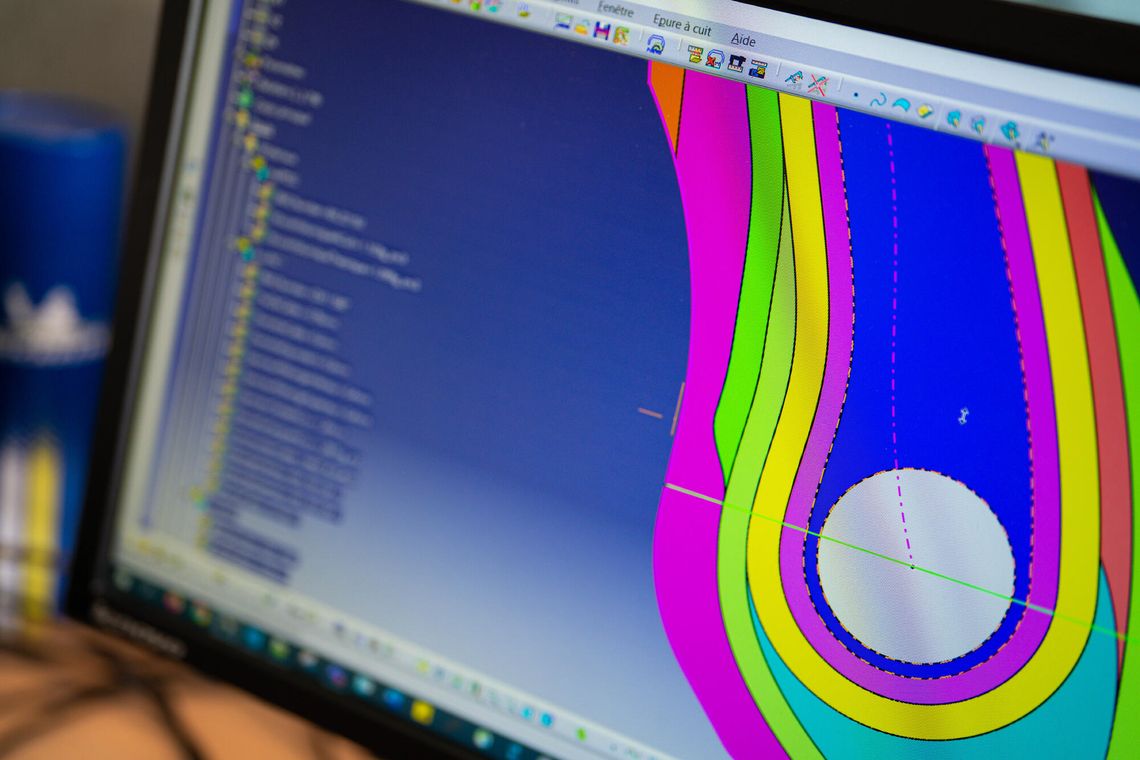

Our know-how in flexible composite product design is based on our unique ability to design products which offer overall structural rigidity while remaining highly deformable locally. It is crucial to be able to manage the constraints of materials with different properties.

Knowhow based on multidisciplinary expertise

A tire needs to be both rigid and highly deformable in order to bear the weight of a vehicle and guide it, absorbing more than 100 million deformations during its usage phase. Tires are the cornerstone of Michelin’s expertise in flexible composite design.

To successfully design a product with the expected level of performance and create distinctive value, it is vital to understand what the product will be used for. From the very outset, Michelin forged strong relationships with his customers which have provided it with unique insights into tire use today.

Moreover, the Group can boast a level of excellence in modelling and characterizing flexible structures resulting in optimum tire weight and endurance and minimum energy loss.

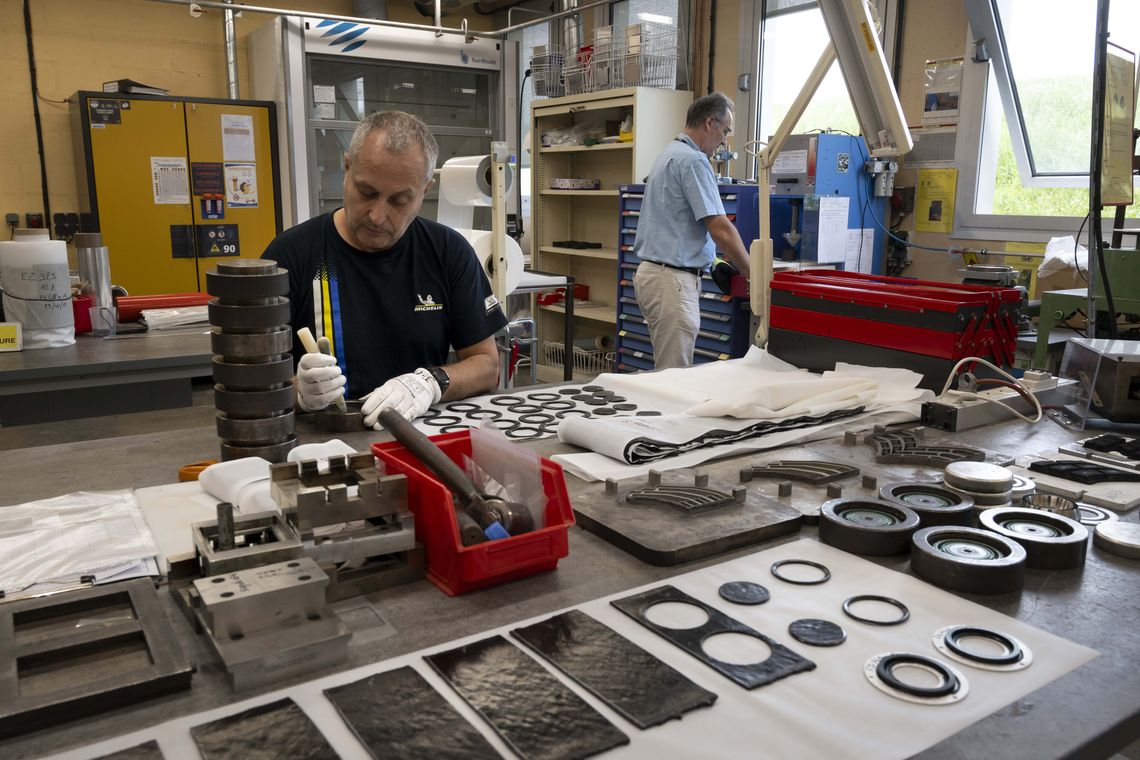

Michelin’s solid expertise in prototyping objects on different scales and its extensive test and measurement capabilities are definite advantages facilitating the transition from virtual to real-life experiences and boosting efficiency in product development. This gives Michelin an upper hand over many manufacturers, enabling it to explore a wide scope of possibilities and consolidate its technological leadership.

Knowhow at the root of the Group’s sustainability strategy

Examples of applications:

MICHELIN Uptis

MICHELIN Uptis combines an aluminum wheel and a flexible load-bearing structure made from glass fiber reinforced plastic (GFRP). Airless - and therefore puncture-proof - it avoids premature tire replacement and vehicle downtime due to flats.

WISAMO

WISAMO is a unique wind-powered propulsion system for ships which uses an inflatable wingsail. It is intended to contribute to decarbonizing shipping by reducing the fuel consumption of merchant navy ships by at least 20%. A 100 m² inflatable wingsail was tested on the Michel Desjoyeaux sailing boat for two years and is now ready for installation on a merchant ship from Nantes in France. An 800 m² wingsail could arrive on the market in 2026.

MICHELIN AirProne inflatable cushions

The Michelin AirProne with its kit of inflatable cushions was designed to offer relief and reduce the risk of pressure sores for patients suffering from acute respiratory distress. Just like tires, the cushions need to be sufficiently rigid to bear the weight of the patient while being deformable so as to keep the patient comfortable.

Fenner Eagle XLD O-ring belting

Eagle XLD O-ring belts are much tougher, offering four times greater load capacity, making them suitable for use in increasingly tough conveying conditions while minimizing downtime and thereby reducing maintenance costs. Michelin bought out Fenner, a world leader in reinforced polymer technology, in 2018.

Becoming a shareholder

Join an extraordinary human adventure that began more than 130 years ago with an innovative Group, leader in sustainable development.

Candidates

Do you want a chance to explore the full scope of your potential and contribute to human progress and a more sustainable world?