Speeding up through open innovation

Michelin not only relies on its internal skills, but also on a wide variety of stakeholders that share its passion for progress in order to speed up innovation to the benefit of a more sustainable future.

Michelin Innovation Lab, a formidable innovation incubator

A collaborative global innovation strategy

Beyond the high level of expertise within its internal teams, Michelin relies on external skills through a network of partners from very different worlds, all committed to a sustainable future: start-ups, small or large companies, research institutes, universities, partners, consortiums, etc. This global, collaborative, and open approach allows the Group to step up its innovative force and its ability to easily spark the ideas that will help to respond to the major challenges of our century.

The research partnerships give us access to the best of external science and technology in order to achieve our ambitions for a sustainable world.

Hundreds of research partnerships serving the Group’s ambitions

Michelin has invested over EUR 44 million in research partnerships across the globe. They are an essential lever for achieving the Group’s growth ambitions, in the tire of course, but also beyond mobility. Collaborations like those with Enviro or Pyrowave demonstrate in particular the Group’s deep-seated desire to speed up the emergence of breakthrough technologies in order to respond as quickly as possible to the major environmental challenges and thus make its 100% sustainable ambitions a reality.

Towards the factory of the future

Inaugurated at the beginning of 2017, the Factolab unites Michelin’s research services with three university laboratories in the Clermont-Ferrand area: the Pascal Institute (IP), the Social and Cognitive Psychology Laboratory (LAPSCO), and the IT, Modelling and System Optimization Laboratory (LIMOS), under the supervision of the CNRS (French National Center for Scientific Research).

Devoted to innovative technologies for the factory of the future, FactoLab implements an R&D program on human-machine cooperation serving operators, in particular in the fields of collaborative robotics, augmented reality and even the design of autonomous transport carts.

On a course for future materials, medicine, and hydrogen

The Simatlab public-private research laboratory, created in 2017 by the Michelin Group and the Clermont-Ferrand Chemical Institute (ICCF), concentrates its works on modelling future materials, medicine and hydrogen; three fields at the heart of the Group’s "All-sustainable approach", in which Michelin both wants to add a great deal of value to its know how and to grow.

Even more sustainable elastomers

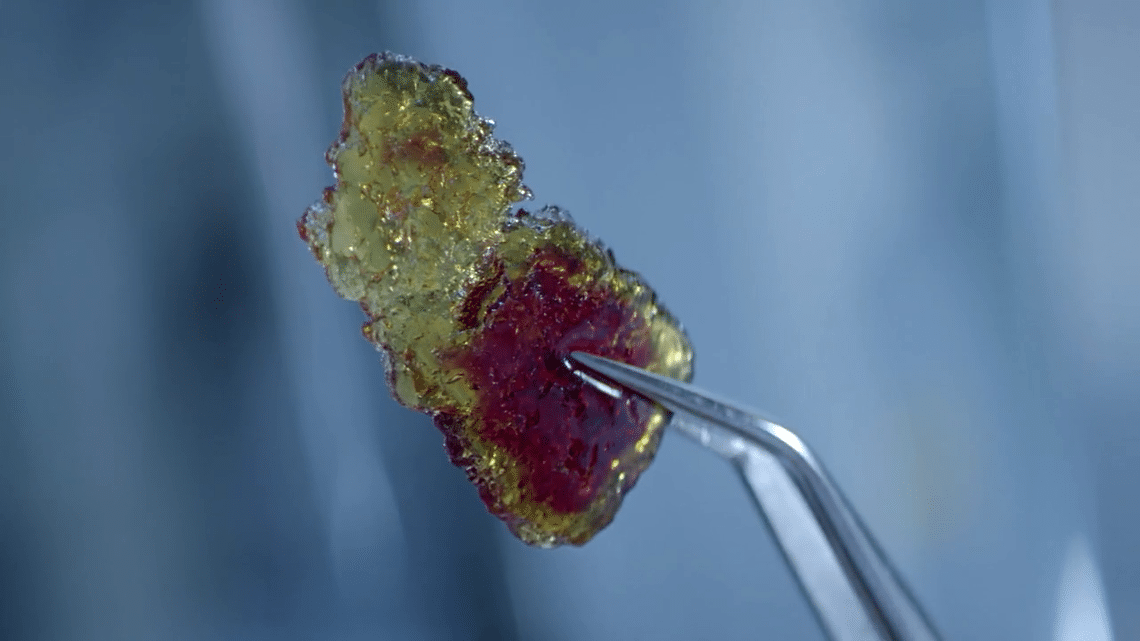

Created in 2019, ChemistLab combines the expertise of Michelin and two university laboratories from Lyon under CNRS supervision: the Chemistry, Catalysis, Polymers and Processes (C2P2) laboratory and the Institute for Molecular and Supramolecular Chemistry and Biochemistry (ICBMS).

This joint laboratory aims to create new generations of high-performance elastomers from bio-sourced raw materials. This approach is unique because it involves all stages of the elastomer’s life cycle, from the choice of raw materials to their ability to be recycled. It uses state-of-the-art simulation techniques and highly advanced polymerization control.

New tires from end-of-life tires

Coordinated by Michelin, the BlackCycle project unites seven industrial partners, five research and technology organizations (RTOs) and an innovation cluster into a European consortium established in five countries (France, Spain, Germany, Greece, and Switzerland). It aims to create a massive circular economy for tires by designing one of the world’s first processes to produce new tires from worn tires.

The consortium will develop specific solutions to produce sustainable raw materials for tires: worn tire collection and raw material selection, pyrolysis optimization, oil refining and recycling, furnace process optimization and performance assessments for the sustainable tires created.

Using carbon black from end-of-life tires

At the Smithers Recovered Carbon Black Conference in Amsterdam in November 2021, Michelin and Bridgestone announced a common “Call to Action” initiative, the objective of which is to establish the conditions allowing for a wider use of carbon black from end-of-life tires in the production of new tires and other rubber-based products.

By working with the industry’s various stakeholders, this initiative has already allowed for defining proposals for the various carbon blacks derived from end-of-life tires.

Becoming a shareholder

Join an extraordinary human adventure that began more than 130 years ago with an innovative Group, leader in sustainable development.

Candidates

Do you want a chance to explore the full scope of your potential and contribute to human progress and a more sustainable world?