Designing and industrializing innovative materials

Reinforcements, cords and cables, all types of polymers.... Michelin has developed specific knowhow in the design, development and production of innovative materials which cannot be found elsewhere on the market.

Materials are structural elements, for example textile or metal reinforcements or polymers, which play a decisive role in the final performance of the finished products.

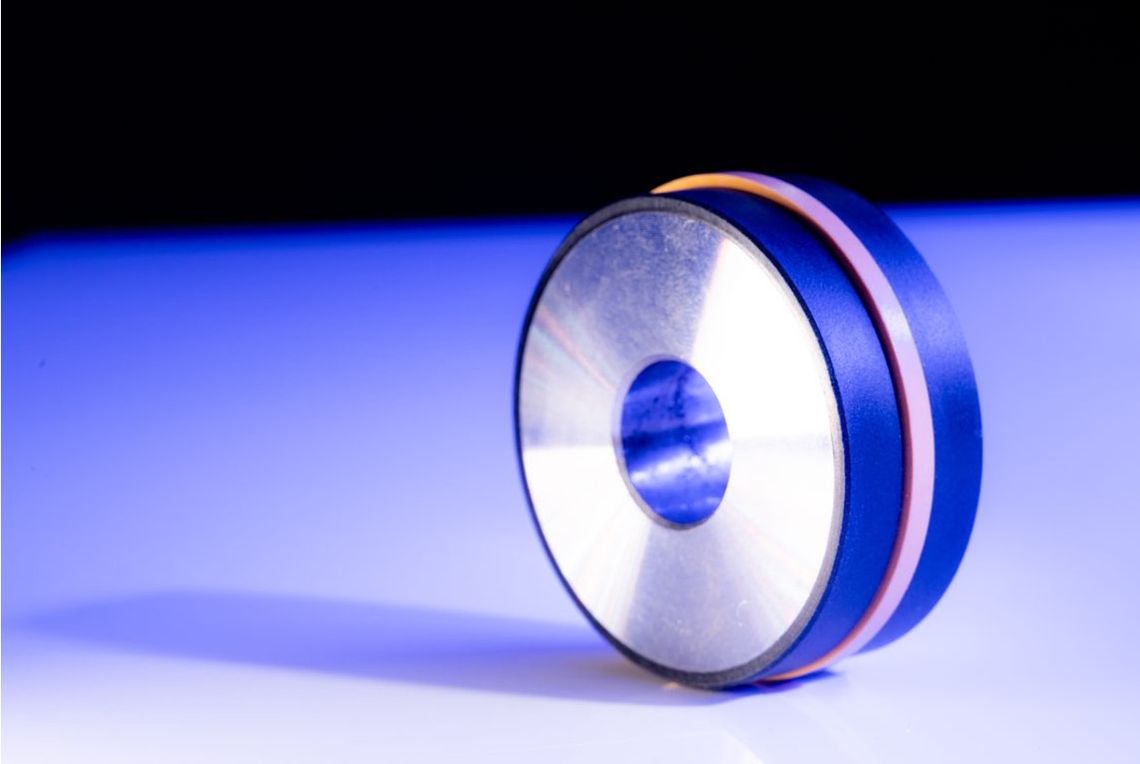

Reinforcements are made of steel cables or textile cords (aramid, PET, nylon, hybrid) or fiberglass. They contribute to improving endurance, longevity and rolling resistance.

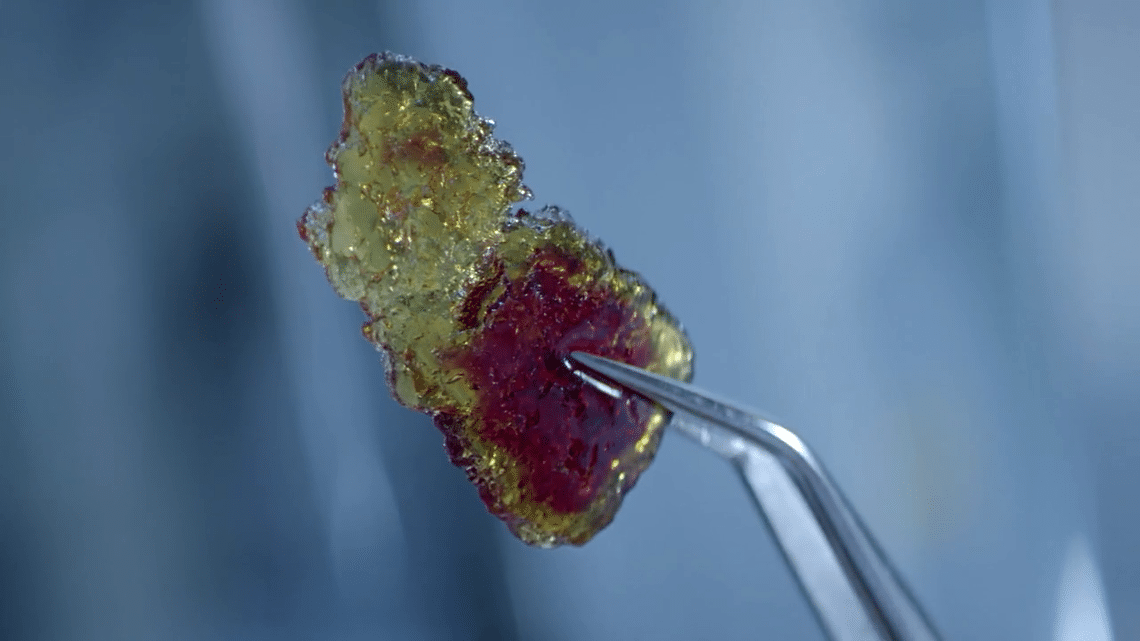

Polymers are long chains of small molecules called monomers. They are ingredients in rubber compounds and help enhance abrasion resistance, rolling resistance and tire wet grip.

Our specific knowhow in materials contributes to our technological leadership and allows us to meet the requirements of demanding fields of application both for tires and beyond mobility.

From material knowledge to exceptional performance

Michelin’s ability to understand all the mechanisms of materials during the usage phase and combine components with seemingly contradictory properties enables it to develop highly innovative products offering exceptional performance. But this is nothing new. As early as 1937, with the Metalic tire, Michelin succeeded for the first time in combining rubber and steel; a decisive innovation for the invention of radial technology in 1946 that would revolutionize mobility.

In 1992, Michelin unveiled a tire with a lower environmental impact thanks to the use of silica. Since then, Michelin has continually increased its tires’ energy efficiency, reducing fuel consumption and therefore CO2 emissions by making use of functional polymers.

Knowhow boosted by a strong drive for innovation

To develop its knowhow, Michelin has built up a solid bedrock of expertise over the decades and encourages a multi-disciplinary approach, harnessing synergies between polymers, chemistry, biochemistry, physico-chemistry, rheology, metallurgy and chemical engineering. The experts in each of these areas pool their knowledge and complement each other. In parallel, the Group makes use of open innovation. Michelin is working with the French National Center for Scientific Research in seven joint laboratories studying subjects such as biodegradability, synthesis and the modeling of new molecules. In collaboration with these joint laboratories, the Group is shaping the polymers which will be used in thirty- or forty-years’ time, most likely with amazing new characteristics.

Michelin is also stepping up its partnerships with innovative enterprises to develop new technology with a view to using more and more renewable or recycled materials.

We are highly involved in multi-stakeholder partnerships enabling to develop access to these renewable or recycled raw materials. This is key to the future deployment of these new materials.

Unique development and industrialization capabilities

Michelin’s ability to manufacture its own reinforcements and polymers on different scales - from producing one gram in the lab to mass-producing several tonnes - is another competitive advantage. The Group has made extensive resources available to its teams to meet its ambitious goals: prototyping workshops to test materials at their different stages of maturity, polymer manufacturing facilities in France, Indonesia and the US.

Becoming a shareholder

Join an extraordinary human adventure that began more than 130 years ago with an innovative Group, leader in sustainable development.

Candidates

Do you want a chance to explore the full scope of your potential and contribute to human progress and a more sustainable world?