Michelin is leveraging its know-how on emerging markets

Firm in its belief that technological progress is one of the solutions to environmental challenges, Michelin invests and innovates to develop new technologies for emerging applications and markets.

Michelin, on the cutting edge of hydrogen

Inspired by its vision of sustainable mobility and powered by its expertise in materials, Michelin has been investing in hydrogen fuel cells for over 20 years. Hydrogen is one of the keys to achieve our objectives for reducing CO2 emissions and air pollution and to enable the energy transition to non-fossil resources.

Becoming a global hydrogen solutions player

As a recognized pioneer in the field, Michelin now aims to become a global hydrogen solutions player and is investing in three areas: hydrogen fuel cell production, the service offer to make the energy transition more accessible for its customers, and infrastructure development.

Fuel cell production: Symbio

Michelin aims to become a global leader in hydrogen mobility systems with Symbio, a joint venture created in November 2019 by Michelin and Forvia (formerly Faurecia) and joined in July 2023 by Stellantis. Symbio aims to achieve €1.5 billion in turnover by 2030 thanks to its production site in Saint Fons, which was inaugurated on December 5, 2023.

Symbio develops, produces, and markets a full line of hydrogen fuel cell systems (StackPack®) for mobility, with a focus on light utility vehicles, trucks, and buses. Hydrogen fuel cells are a technology that emits only water during the entire vehicle use phase.

Service offers: Watèa

Through its connected solutions for vehicle fleets, Michelin has an offer called “Watèa by Michelin” which supports professionals in their energy transition.

In December 2022, Michelin opened up the capital of Watèa—its subsidiary that specializes in the transition to battery-powered electric, and soon hydrogen, mobility for professional vehicle fleets—to Crédit Agricole Leasing & Factoring.

Infrastructure development

The Group also plays a unifying role, bringing companies, regions, and countries together to make hydrogen mobility accessible and enable its roll-out to all types of transportation.

That commitment is best illustrated by the “Zero Emission Valley” (ZEV) project in the Auvergne-Rhône-Alpes region, which aims to create an adequate local network of charging stations. The project, which is spearheaded by the company HYmpulsion, in which Michelin is a shareholder, recently received several subsidies from the EU (€10.1 million) and the French government (Ademe: €14.3 million and €2.1 million). The region currently has 4 operational stations and the HYmpulsion station in Gravanches was inaugurated on July 5, 2023.

Developing the hydrogen industry and making it more sustainable

Michelin innovates in High-Tech Materials to make the hydrogen sector more sustainable. To that end, Michelin and the CNRS (National Scientific Research Center) inaugurated HydrogenLab, a new joint academic research laboratory whose purpose is to design a new generation of materials for Membrane-Electrode Assemblies (MEA), the core component of hydrogen fuel cells and Proton Exchange Membrane (PEM) electrolyzers.

Michelin also works to foster cooperation among hydrogen industry players in France and worldwide. Its involvement at the European level as a member of Hydrogen Europe, the association of European hydrogen sector companies, and the European Clean Hydrogen Alliance, as part of the deployment of the European strategy initiated by the European Commission. The Group is also strongly invested in France Hydrogène, the French hydrogen association.

MICHELIN, a major player in metal 3D printing

3D metal printers produce parts that cannot be manufactured using traditional processes. They also offer industrial players a wide range of additional benefits, including materials savings, increased design flexibility, and agility. That is why we believe in the potential of the development of metal 3D printing.

Over two decades of experience in metal additive manufacturing

Michelin first used metal additive manufacturing in the early 2000s to produce complex sipes in its curing molds, a technology that is now found in many of its truck, car, and motorcycle tire ranges.

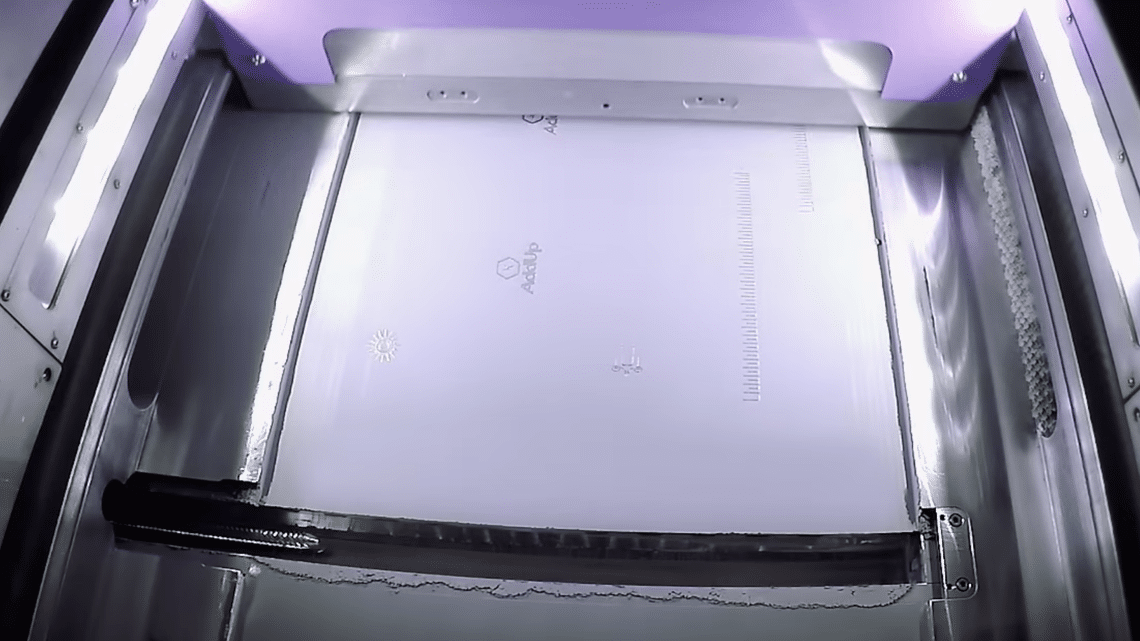

In 2016, Michelin teamed up with Fives, the leader in industrial machine design and production, to create AddUp, a joint venture that specializes in metal 3D printing. Michelin is now on the cutting edge of metal additive manufacturing technology and is expanding into fields beyond tires.

AddUp has drawn on the expertise of Michelin and Fives to become a major player in metal additive manufacturing.

With its 2018 acquisition of BeAM, AddUp added a new technology that complements powder bed fusion: Directed Energy Deposition. Its business is now based on two types of technology: Powder Bed Fusion (PBF) and Directed Energy Deposition (DED). AddUp’s innovative multitechnology production systems are designed to produce extremely precise parts and optimize productivity.

They are fully integrated into a digital environment and offer innovative ways to solve the most complex challenges. In addition to its full line of machines and parts production, AddUp also offers a selection of support services for industrial players that want to develop metal 3D printing for industrial series production.

A technology now serving new markets

Michelin: decarbonizing the maritime industry with WISAMO

With its innovation “WISAMO - Wing Sail Mobility,” Michelin aims to contribute to decarbonizing maritime shipping by using a wind propulsion solution to reduce its environmental impact.

WISAMO: Michelin's expertise in materials is advancing maritime decarbonization

WISAMO, which draws on the Group’s innovation prowess and its historic expertise in high-tech materials, particularly for inflatable structures, fits perfectly into Michelin’s “All-sustainable” approach. The Group, which ships its tires by sea, aims to reduce the environmental impact of its supply chain.

WISAMO also showcases Michelin’s ambitions for growth in new areas, as laid out in its “Michelin in Motion” strategic plan.

Understanding the WISAMO system

Don't miss anything!

Candidates

Do you want a chance to explore the full scope of your potential and contribute to human progress and a more sustainable world?