Michelin and the all sustainable tire

Michelin is responding to the climate emergency by pledging to design and mass produce all sustainable tires by 2050. But what actually is a sustainable tire?

For Michelin, using sustainable - recycled or renewable bio-based - materials in its tires still does not make them all sustainable; tires need to have as little impact as possible on the environment throughout their entire lifecycle. All sustainable tires must be designed for longlasting performance from the first mile until the tread wear limit so as to use less materials and energy and avoid having to replace tires too early. All sustainable tires must offer the same - if not better - safety performance than today’s tires. Lastly, all sustainable tires must be suitable for mass production, not just available in small quantities or in particular models.

Making our tires fully sustainable is certainly one the main challenges we face! But who better than Michelin to find the right solution?

Lifecycle analysis: an essential step

For Michelin, designing an all sustainable tire means reducing its environmental and social impact based in particular on the lifecycle analysis from tire design through to its manufacture, transportation, use and recycling.

The use stage of a tire alone accounts for between 75% and 90% of the overall environmental impact. Supplying tires which offer top performance from the first mile to the tread wear limit is part of Michelin’s DNA and is one of its competitive advantages thanks to its know-how in materials and tread design. In Europe alone, 128 million* tires and 6.6 million* tonnes of CO2 emissions would be saved if all tires were used right down to the legal wear limit of 1.6 mm**. In fact, for more than 30 years now, Michelin has been systematically improving the rolling resistance of its tires, making a major contribution to saving energy and money. Tire rolling resistance accounts for the equivalent of one full tank of fuel out of five. In the design stage, Michelin uses virtual testing to speed up tire development. A pioneer in modeling and simulation systems, Michelin is capable of simulating tire behavior in the most extreme situations. This means fewer prototypes and tests, thereby saving on CO2 emissions. Michelin used simulation technology to develop certain recent lines (Pilot Super Sport, Pilot Sport Cup) for manufacturers like Ferrari, AMG, Porsche, Corvette, Lexus, Ford Performance, and more. As for manufacturing, Michelin has pledged to reduce the environmental impact of its sites and, by 2050, is aiming to achieve net zero CO2 emissions for all its plants*, zero impact on water availability in the areas where it operates and the total elimination of solvents in the tire production process. |

Better and alternative transportation is another commitment made by the Group which aims to slash CO2 emissions in logistics by 15% by 2030 compared to 2018. To achieve this, Michelin will rely on a local-to-local production strategy. |

Lastly, Michelin is investing in regenerating the materials used in tires and re-injecting them into new tire production by actively contributing to developing the recycling sector and fostering the emergence of disruptive technologies in collaboration with various partners. |

* Data taken from an Ernst & Young report “Planned obsolescence is not inevitable” - May 2017 |

** conditional upon uniform tire wear and compliance with tire manufacturers’ and automotive manufacturers’ recommendations. If in doubt, consulted a specialist. Ministerial order of 18/09/1991 amending the order of 29/07/1970 regarding the characteristics and conditions of use of vehicles and their trailers, Official Journal of 08/10/1991. |

Integrating renewable or recycled materials without compromising on performance

Of course, a "sustainable tire" cannot be conceived without the use of renewable or recycled materials. To date, there are no guidelines or regulations governing this term. In order to place the environmental cursor as high as possible, Michelin considers that a material is only truly sustainable if it is recycled or renewable over a human lifetime. One of the major challenges is to find alternatives to the components currently used in tyres, which do not impair tire quality or performance, particularly in terms of safety. Michelin can leverage its extensive know-how in high-tech materials (3,678 material-related patents filed at the end of 2021). The Group is also investing in startups and concluding multiple partnerships with innovative companies: Pyrowave (r-styrene), Carbios (r-PET), Enviro (rCB etc.) in order accelerate disruptive technology. Michelin pays close attention to its sourcing and has been evaluating supplier CSR performance for more than ten years now. At the end of 2022, 87% of its main suppliers were in compliance with the standards laid down by the Group. |

Renewable or recycled materials, according to Michelin

Recycled materials: styrene regenerated from waste polystyrene (yoghurt pots, food trays, packaging, etc.), textiles regenerated from PET* waste (plastic bottles, dispensers, etc.), carbon black recycled from end-of-life tires.

Renewable materials: natural rubber from a responsible industry, butadiene (or bio-butadiene), products made from biomass (plant waste).

*PET : Polyéthylène Téréphtalate

Scaled-up production

Michelin factors in the environmental impact of its tires at each stage of their lifecycle but also ensures that industrialization can be scaled-up so that everyone can benefit.

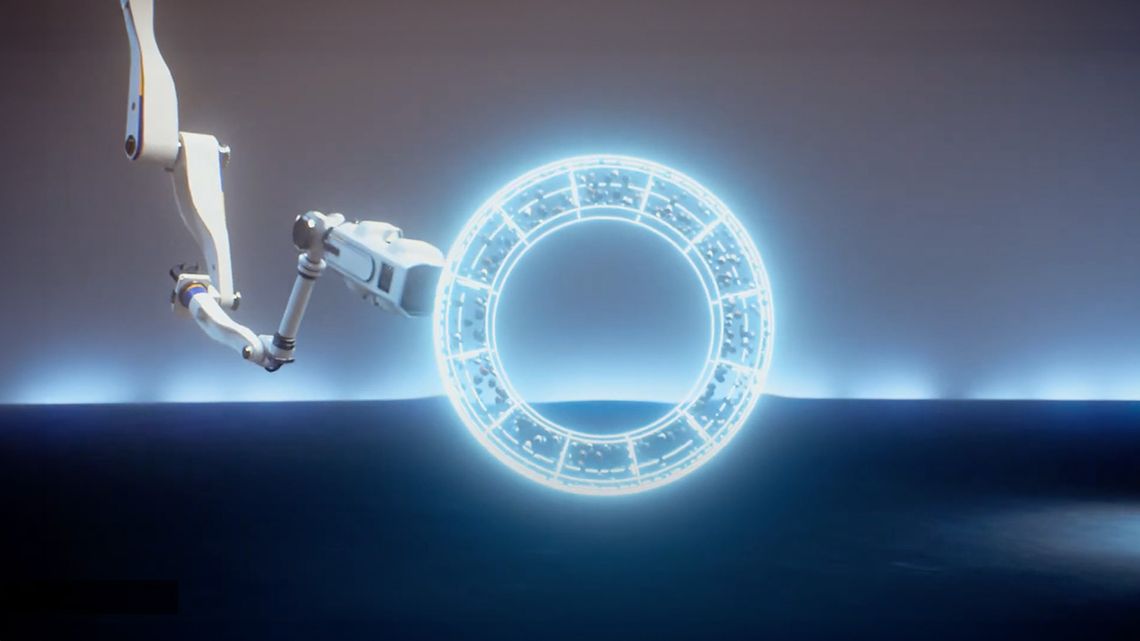

The idea is not to make a splash with a show tire.

At the end of 2022, Michelin presented car and bus tires homologated for road use containing 45% and 58% renewable and recycled materials respectively. The technology used will be transposed onto the tires arriving on the market in 2025.

For the 2023 season, Michelin supplied tires for the world MotoE™ championship containing 52% of renewable and recycled materials and capable of reaching track speeds of 250 km/h. Another example is the Mission H24 hydrogen prototype and the Porsche GT4 ePerformance fitted with tires containing 63% renewable and recycled materials.

Dream or reality? For Michelin, creating a fully sustainable tire may seem pretty ambitious but it is definitely within our capabilities. Over and beyond its alternative holistic approach based on lifecycle analysis, the Group can count on many other advantages: unique expertise in materials, an R&D powerhouse with as many as 6,000 engineers, researchers, chemists and developers across several continents as well as high-level experience in Motorsports, a proving ground for sustainable innovations. Michelin can also rely on carefully chosen partnerships and programs allowing it to speed up the implementation of disruptive technologies.