DECODING

min

/

Published on 01/11/24

Michelin is taking action to reduce tire wear particle emissions

Michelin has been keeping a close watch on the issue of tire wear particles for many years; these are the particles which are generated by friction between the tire and the road surface. The Group is the leader in this field and is striving to reduce the phenomenon of abrasion, by leveraging its expertise in materials and advocating changes to the regulations.

Good tire grip on the road is essential for driver safety. But this road grip has physical consequences: it generates tire wear particles due to the friction between the tire and the road surface. This is known as abrasion and the particles generated are Tire and Road Wear Particles (TRWP).

Various factors can exacerbate abrasion such as tire quality, driving behavior, the type of road surface and tire pressure.

What are tire wear particles made up of?

According to the definition of the European Chemicals Agency (ECHA), tire wear particles belong to a subcategory of microplastics. However, their properties are quite different from the microplastics which are a byproduct of the plastics we encounter in everyday life (bottles, packaging, textiles etc.) in particular in terms of degradability, size, composition and density.

These particles consist of equal proportions of tire tread debris, minerals and dust from the road surface measuring between 80 and 100 microns (the equivalent of a hair’s breadth); by comparison, the average diameter of microplastics is 5 microns.

Their biodegradation rate is much quicker too (50 % of tire wear particles disappeared within 16 months)(1).

Their physical properties mean that they fall to the ground quickly which limits the quantity of airborne particles. However, there is a risk of them being discharged into the aquatic environment.

Do tire wear particles contribute to air, soil and water pollution?

To correctly assess the contribution of wear particles to air, soil and water pollution, the studies based on direct measurement of samples must be dissociated from extrapolations based on statistical models which do not use real-life data.

As far as air pollution is concerned, the various studies carried out by the Tire Industry Project (TIP) and other research bodies all reach similar conclusions. The TIP was set up fifteen years ago in order to study cross-cutting issues concerning the entire tire industry (wear particles, end-of-life tire recycling etc.). Eleven of the world’s largest tire manufacturers are members under the auspices of the World Business Council for Sustainable Development (WBCSD).

The findings of these international studies conducted in different countries(2) show that tire wear particles do not significantly contribute to air pollution and in fact are only found in minuscule quantities in urban pollution: less than 1% of PM10 and less than 0.3% of PM2.5 on average (PM = particulate matter).

As far as soil and water pollution is concerned, this depends on the distance between the emission zones and the estuaries. It appears that between 1% and 13% of wear particles end up in the ocean.

Studies carried out since 2019 reveal that a substance called 6PPD-Quinone is toxic for certain marine species (Coho salmon).

This substance is apparently produced during the transformation of an antioxidant (6PPD) used in tires which plays an important role in safety. These studies are not yet able to explain the mechanism of toxicity.

Michelin has pledged to reduce the environmental impact of its products and activities and launched a special research program in 2022 to identify a substitute for 6PPD.

Thanks to Michelin’s longstanding expertise in materials, i.e. our ability to use fewer materials in our tires to make them more lightweight while delivering products that last longer and perform better, the Group has succeeded in keeping tire abrasion in check resulting in a 5% reduction in particle emissions from its products between 2015 and 2020.

Michelin, unchallenged leader in particle emission reduction

Factoring in the environmental impact of its products is part of Michelin’s DNA and forms an integral part of corporate strategy. The Group has been closely following the findings of scientific studies on TRWP for many years and stays abreast of all issues related to wear particle emissions and their impact on the planet.

New information is emerging, contributing to a better understanding of the impact and risks associated with tire abrasion but Michelin has not waited for this to take action: the company has been working on reducing abrasion for many years - right from the design phase.

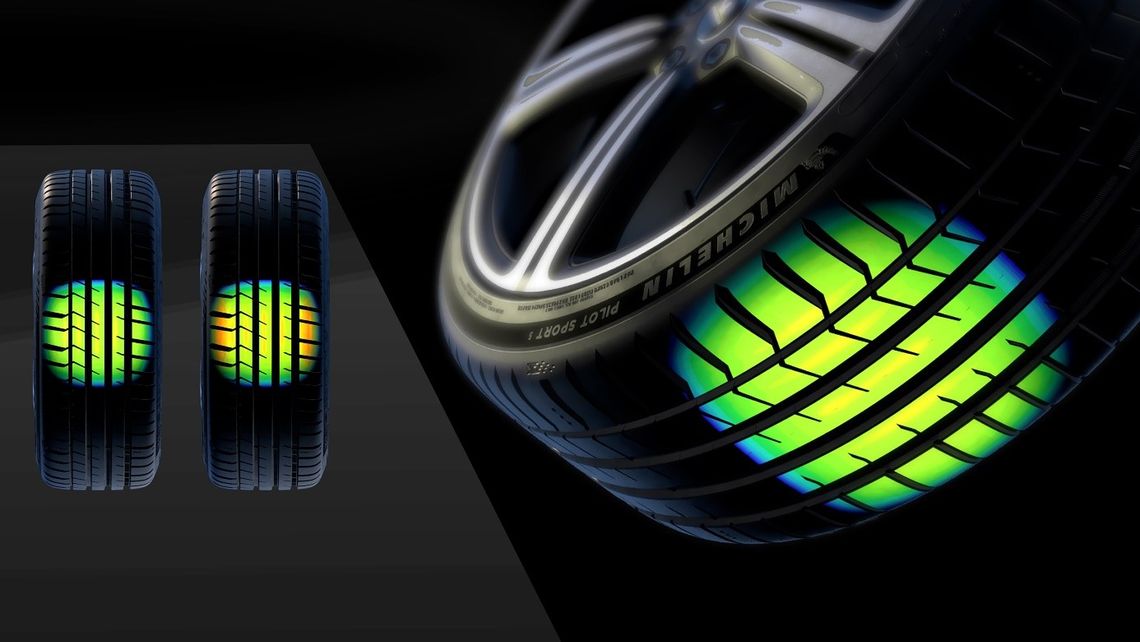

To achieve this, Michelin has capitalized on its know-how in formulating synthetic rubbers (functionalized SBR*) and optimizing tread patterns so as to reduce the amount of rubber used.

Michelin also makes use of simulation techniques on the contact patch to reduce slippage and limit tire abrasion.

*Styrène Butadiène Rubber

This policy made it possible to slash TRWP emissions in Michelin products by 5% between 2015 and 2020. This represents a global aggregate saving of 100,000 tons of particles. In the medium-term, Michelin is working on developing new bio-assimilable materials, significantly limiting the potential impacts of particle emissions.

Michelin, a key player driving the progress of the entire tire industry

The Group has long been in favor of defining regulatory thresholds for tire abrasion so as to limit tire wear particle emissions worldwide. In this respect, Michelin supports the recommendations of the European Commission encompassed in the Euro 7 standard to adopt tire abrasion limits.

Michelin and its competitors, fellow members of the European Tyre and Rubber Manufacturers' Association (ETRMA), have agreed upon the definition of a method for measuring particle emission performance for passenger cars. It is a robust, reproducible method which reflects average usage in Europe, expressed in mg/km/T.

The Group is involved in the Tire Industry Project with other tire manufacturers but also helps fund studies conducted by other bodies to further scientific understanding of wear particles.

- 20 %

Reduction in particle emissions of the MICHELIN e-Primacy range compared to the previous range, the MICHELIN Primacy 4

- 25 %