Michelin Innovation Lab

The MIL’s role is to detect and support new internal projects liable to boost Group growth in the medium to long term.

From the spark of an idea to a fully-fledged business

The candidates pitch their project to a jury of middle managers. If it is validated, it is taken on by the Michelin Innovation Lab which manages the proof-of-concept stage lasting roughly three months. Next, the employee refines their project and business plan with the help of a coach before submitting it to a second jury, made up this time of corporate decision-makers in a position to finance the project. If this second pitch is approved, the employee leaves their job (but not the Michelin company) to devote themselves to their initiative full time. They become an intrapreneur and can benefit from training leading to certification.

The project then enters its incubation phase. A “kick-off” budget is attributed to the project to allow the intrapreneur to explore the idea for about 18 months. The first step is to gather sufficient information for the sponsor to agree to continue funding the project. The aim is to quickly demonstrate the desirability, feasibility and economic viability of the initiative. The project team gradually takes shape; staff are hired and a growth strategy is defined.

And if all goes to plan, there will come a time when the project is mature enough to scale up to become a fully-fledged business.

Failure is inevitably part of our philosophy. Our method is based on derisking and halting an initiative is never a bad thing. The intrapreneur always learns something from this experience. We are proud of our achievements, some of which have excellent perspectives for growth. Michelin Innovation Lab is above all an exciting human adventure!

Collaborative and open innovation

The Michelin Innovation Lab relies on collaborative innovation and collective intelligence. Thanks to a platform called NewBiz, people in different business lines and in different countries can submit ideas. Innov’Up Challenges encourage Group employees to come up with ideas for new products and services during campaigns launched by the business entities. Open Innovation also fuels the Michelin Innovation Lab via a network of external partners (researchers, students, start-ups, consortia etc.) boosting the Group’s capacity to facilitate the emergence of new ideas; adding to its know-how and diversifying the source of innovations. The Michelin R&D department works closely with three university labs in Clermont-Ferrand in FactoLab, under the auspices of the French National Center for Scientific Research CNRS. ChemistLab is a joint laboratory operated by Michelin and two Lyon universities tasked with developing new generations of elastomers. Michelin coordinates the BlackCycle project bringing together seven industrial partners, five research organizations and an innovation hub in a European consortium. The purpose of this project is to develop the circular economy of the tire. |

ResiCare, Wisamo, Watèa by Michelin… just some of the successful ventures incubated by the MIL

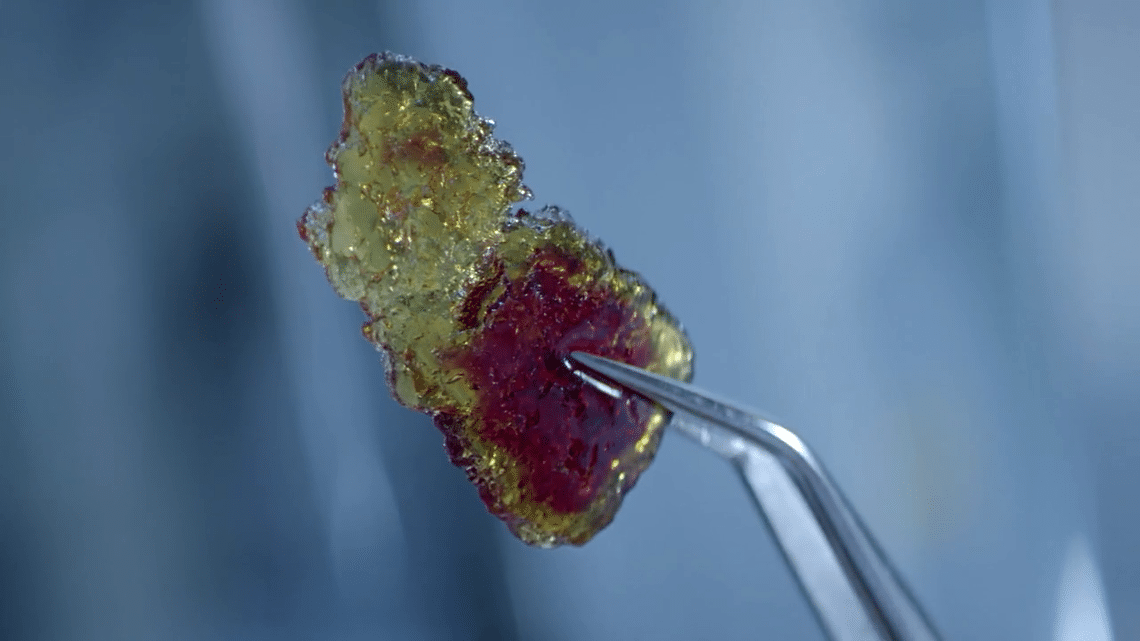

The MIL was responsible for ResiCare, a Michelin Group brand which develops and markets a high-performance adhesive resin which is non-toxic and bio-based, for industrial applications. This glue was first used by Michelin in its textile tire reinforcements and in fact, by 2025 80% of the glue used by Michelin should be ResiCare. It has been successfully adopted by the timber industry.

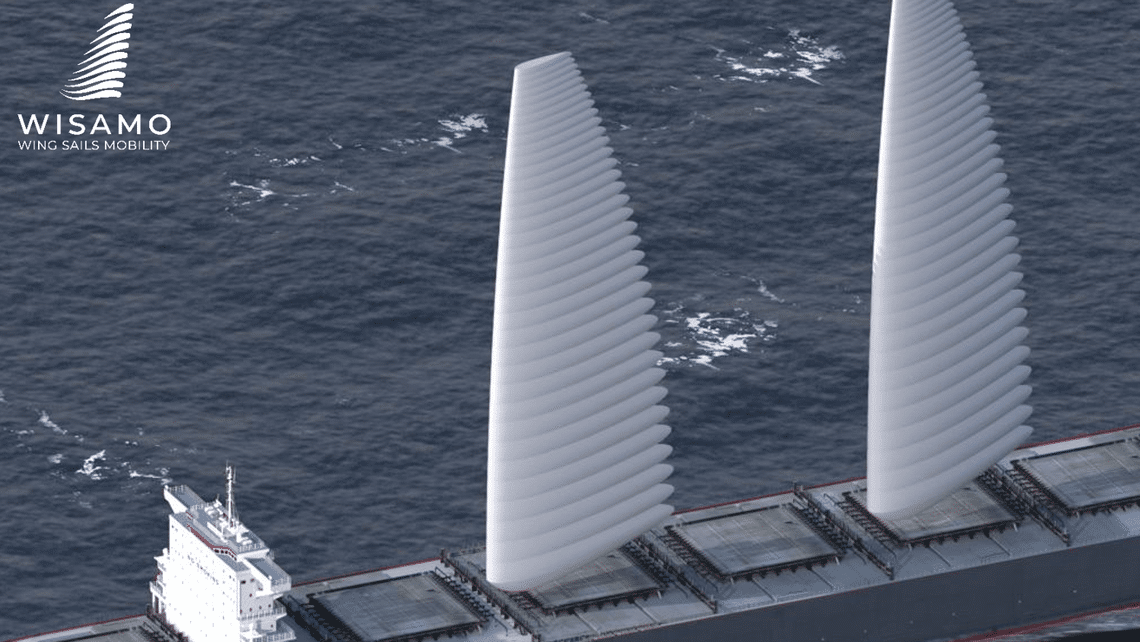

Wisamo (Wing Sail Mobility), a wingsail propulsion system designed to contribute to decarbonized maritime shipping is another idea originating in the Michelin Innovation Lab. The inflatable wing, with its telescopic mast steered via a connected interface, offers environmentally-friendly power assistance for merchant ships. Skipper Michel Desjoyaux tested a Wisamo prototype on his own sailing boat, concluding that: “it’s more than just a wing, it’s a fully automated wind-powered engine.” Development is going full steam ahead and the Michelin Vannes site has been selected as the manufacturing facility.

Watéa is another good illustration of sustainable mobility. It is a zero-emission all-in-one mobility solution for professional fleets. Watèa by Michelin consists of a pack of integrated services: journey analysis, recommendations of suitable electric vehicles, identification of the best financing solutions, vehicle deployment, access to charging infrastructure and a digital platform to help operators and drivers manage their business more easily.