We race for change

min

In addition to scoring more than 1,200 major victories in association with many of racing and rallying's biggest players, Michelin Motorsport has a long tradition of contributing to enhanced mobility. Today, more than ever, it stands out as an invaluable resource for exploring new ideas and accelerating technological innovation, while the sport itself is undergoing profound changes.

Racing against the clock for the environment

In the course of its century-plus history, Michelin has collected an enviable collection of silverware, with more than 1,200 victories in major events across a wide spectrum of disciplines and conditions (circuit racing, rallying, deserts, snow and ice, etc.). Having demonstrated the quality of its tires in world-class motorsport, the company is today focusing the clout of its research resources on innovating in favor of the environment.

REWIND

Michelin can look back at a proud record of more than 100 Formula 1 grand prix victories, plus five times that number in topflight motorcycle racing (500cc / MotoGPTM), more than 300 more in world-class rallying and hundreds in endurance racing, including every Le Mans 24 Hours win since 1998. While forging this unrivaled record, Michelin has been active in many of motorsport history's most memorable moments thanks to its instinct for innovation, unique expertise, quest for excellence, passion and game-changing ideas.

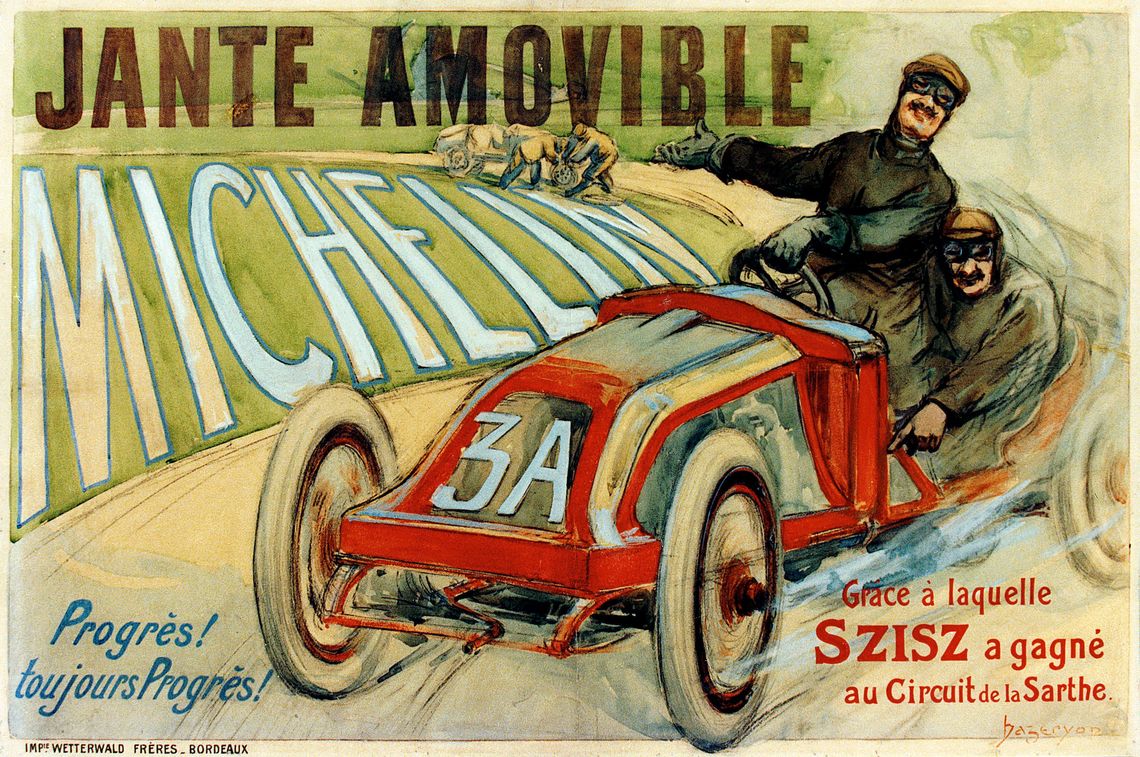

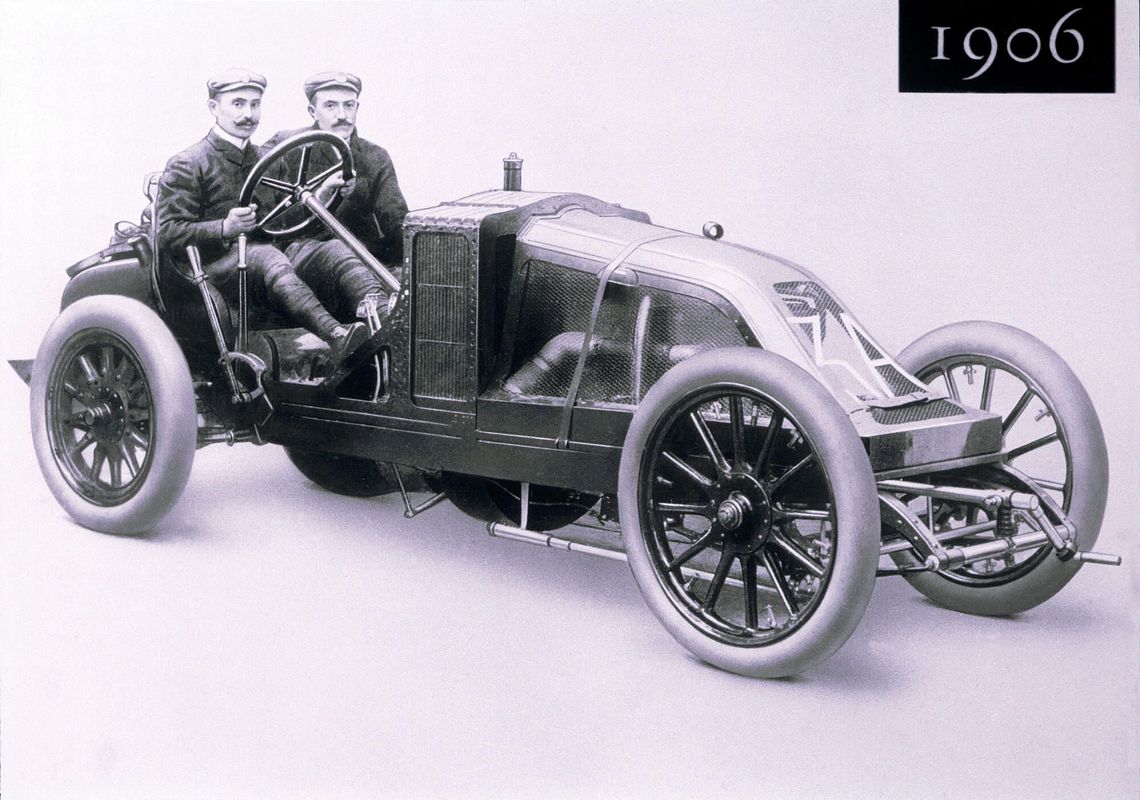

1906: Michelin's first major motor racing success!

Prior to the first-ever Grand Prix Automobile de France in 1906, near Le Mans, Michelin patented a removable rim that was the envy of its day. It meant tires could be changed in four minutes or less, compared with a good quarter-of-an-hour in the case of a conventional assembly. After two days of intense, grueling action, the grand prix was won by Hungary's Ferenc Szisz in a Renault AK on Michelin tires... and removable rims.

Motorsport: a laboratory of extremes

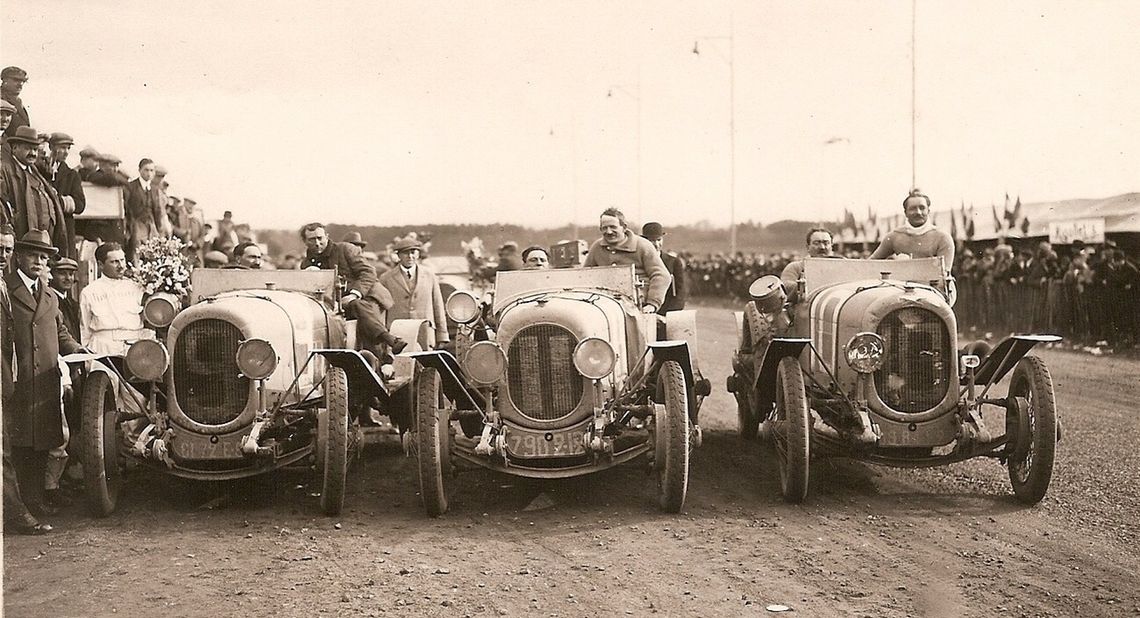

History's first Le Mans 24 Hours won by Michelin

Organized in May 1923, the inaugural Le Mans 24 Hours (originally known as the Grand Prix d’Endurance-Coupe Rudge Whitworth) saw André Lagache/René Léonard and Raoul Bachmann/Christian Dauvergne claim an assertive one-two finish in their Michelin Le Confort-equipped Chenard et Walckers after more than 2,000 kilometers of non-stop racing.

From the outset, the uncompromising French race has stood out as the perfect laboratory for testing and evaluating new technologies in extreme conditions. In 1967, Michelin introduced radial sicks tires to Le Mans, fitted to an Alpine A210 prototype. These pattern-less tires developed exclusively for motorsport delivered exceptional grip in dry conditions thanks to the specific compounds and high-performance materials they featured.

From track to street...

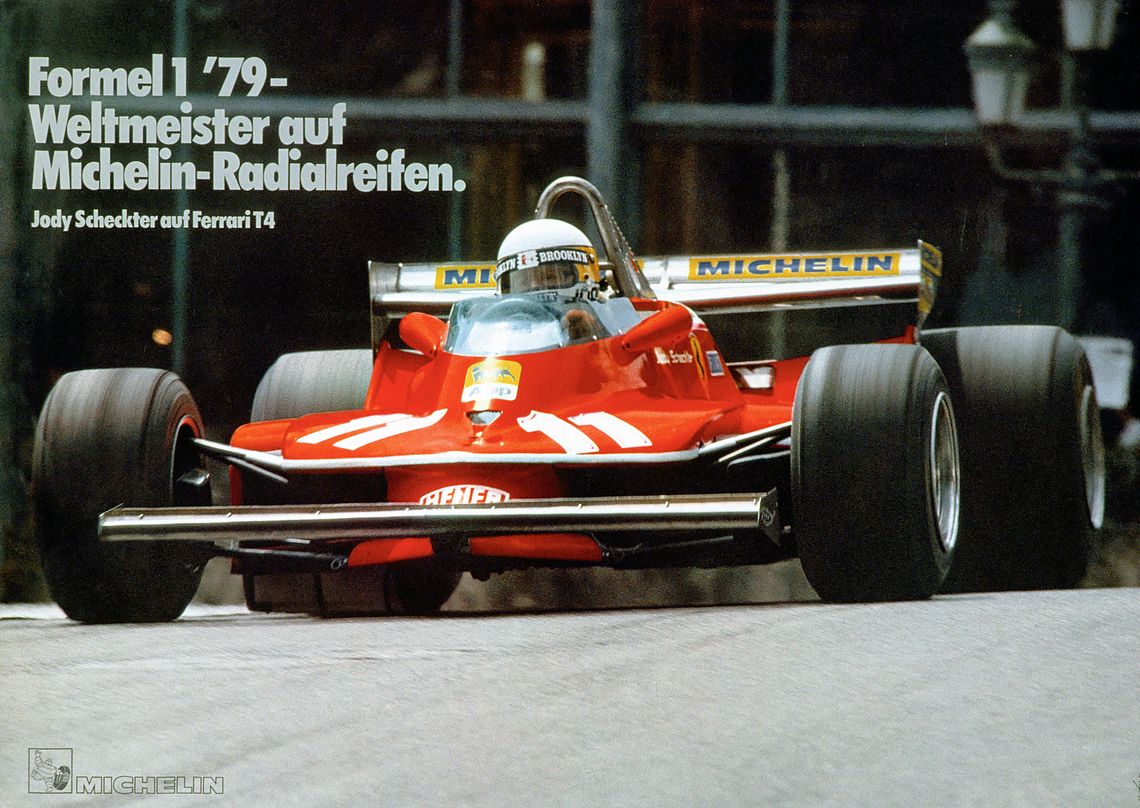

Michelin radial slicks played a part in winning the inaugural World Rally Championship title, in 1973. The following season, the technology was also seen in grand prix motorcycle racing. In 1978, it won Formula 1's Brazilian Grand Prix with Ferrari, in addition to coming first at the Le Mans 24 Hours with Renault-Alpine. A year later, Ferrari and Michelin X technology secured the Formula 1 world crown. Motorsport contributed significantly to the expansion of radial tires which would soon be adopted by the truck, motorcycle, agricultural vehicle, civil-engineering vehicle and aviation industries, etc.

Michelin's emphasis on innovation harvested further success and titles in Formula 1 with Ferrari, Renault, BMW, McLaren. At the same time, the French tire manufacturer dominated its rivals in grand prix motorcycle racing in association with Suzuki, Honda and Yamaha. It triumphed in world-class rallying, too, with Lancia, Toyota and Audi, which established four-wheel drive as the norm. Michelin was equally successful in endurance racing alongside the likes of Mercedes and Peugeot, and took every vehicle-category win on the Paris-Dakar Rally. Many of the innovations trialed in motorsport at the time proved to be genuine mobility changers finding applications in the world of everyday tires.

We race for change

« We do not race for glory, but for change».

Michelin deeply believes that technological progress is one of the most effective ways to address the environmental challenges we face today. It ranges from experimenting with renewable and recycled raw materials, to implementing new, increasingly environmentally-respectful processes, while working closely with vehicle manufacturers as they tackle the ecological transition… In addition to its pursuit of victory, Michelin sees motorsport as a real ally in the race against time to protect the environment.

Motorsport enables us to acquire the sort of specific knowledge that only competition can bring, working with exacting vehicle manufacturers and partners who are addressing the same challenges in the interest of sustainable, increasingly decarbonized mobility

Over the past decade, Michelin has stepped up its involvement in ambitious technology projects in favor of the environment as it rolls out its all-sustainable plan.

FIA Formula E

FIA Formula E

Michelin was a founding partner of the FIA Formula E Championship which was run for the first time in 2014. The idea of racing all-electric cars around street circuits dovetailed perfectly with the group's Everything Sustainable plan.

No tire existed in the Michelin catalog for FIA Formula E's new electric single-seaters, so engineers, chemists and development experts from MICHELIN Motorsport and the Ladoux Technology Center took on the challenge to conceive one from scratch. Aided by the progress achieved in the field of simulation technology, the end-result was the MICHELIN Pilot Sport EV which was ready in time for motor racing's first-ever ePrix.

Building on the experience it acquired in FIA Formula E, Michelin went on to develop the MICHELIN Pilot Sport EV range of road tires that has emerged as a benchmark in today's electric and hybrid vehicle market.

MissionH24

MissionH24

Launched in 2018, MissionH24 is paving the way for an exciting new future for motor racing with the development of a hydrogen, fuel-cell powered prototype and a bespoke class for such cars at the Le Mans 24 Hours. Group Michelin got involved from the outset, on two fronts.

Michelin's fuel-cell specialist subsidiary Symbio and the Michelin brand itself are both actively involved in the project, with the latter behind the development of a specific racing tire for the MissionH24 car that incorporates renewable and recycled raw materials. In June 2022, the prototype completed a lap of the Le Mans 24 Hours circuit to establish a reference time for the 13.6-kilometer track for a car of this type. Race Control clocked a top speed of 290.8kph down the infamous Mulsanne Straight!

The same prototype competed in the Road to Le Mans support races, completing three laps on Michelin tires that contained 53 percent renewable/recycled raw materials. By the following year, Michelin had succeeded in increasing this proportion to 63 percent, with no fall-off in performance. The prospect of a hydrogen car actually competing at Le Mans by 2026 is by no means a pipe dream!

MotoE™

MotoE™

In 2019, Michelin was named partner of the FIM MotoE™ World Cup, the first world-class racing series for electric motorbikes.

Michelin provides MotoE™ competitors with specific, durable yet increasingly high-performance tires. Today, Michelin's front and rear tires respectively contain 34 and 52 percent renewable and recycled materials .

The average proportion of renewable/recycled materials (including natural rubber, rice husk, citrus peel, pine resin and recycled scrap steel) that go into MICHELIN's MotoE™ front and rear tires exceeds 40 percent.

Porsche GT4 ePerformance

Porsche GT4 ePerformance

Michelin and Porsche have been partners in the world of motor racing for more than 20 years. Not only do they boast an outstanding results record together, but they also share the same clear, zero-emissions vision for the sport's sustainable future.

When Porsche first spoke of its Mission R project and Porsche GT4 ePerformance concept, Michelin immediately rose to the challenge of providing the 1,000-plus horsepower, all-electric Cayman 718 GT4 with bespoke '53' tires (53% renewable and recycled raw materials).

The Porsche GT4 ePerformance was unveiled at the 2022 Goodwood Festival of Speed in the south of England. It subsequently embarked on a world tour of demonstration runs, including an appearance at the snowy Race of Champions in the Arctic Circle, for which Michelin provided it with a studded version of its '53' tire.

Acutely aware that sustainability requires a combination of longevity and performance, Michelin is involved in various forms of topflight motorsport - on two and four wheels - where technological excellence is making a real contribution to the sustainable mobility cause. The list of series includes the MotoE™ and FIA World Endurance Championships, where the resilience and durability of Michelin's tires are put to an extreme test fitted to demanding, sophisticated bikes and cars in the hands of exacting riders and drivers. The knowledge acquired in these highly competitive arenas is ultimately beneficial to the brand's everyday tires.

Performance Made to Last

Lasting performance! In environmental terms, the chief quality of any product is arguably its ability to last. In Europe alone, Michelin estimates* that 128 million tires and 6,6 million tonnes of CO2 emissions could be saved if all tires performed all the way down to their statutory wear indicator bar ( minimum groove depth: 1.6mm). Conceiving safe road and racing tires that perform from the first to the last kilometer has long been a part of Michelin's DNA.

*Source: in-house calculations carried out at the Ladoux Technology Center near Clermont-Ferrand, France, published in a Technical Paper dated September 27, 2016, entitled Raw Materials, Fuel Consumption and CO2 Emissions Linked to the Early Replacement of Automobile Tires.

Michelin has always believed that designing longer-lasting tires results in fewer tires having to be produced. This in turn equates to substantial raw material, energy and associated CO2 emissions savings. In the worlds of racing and road tires alike, conceiving products that deliver high performance across their lifespan means having to replace them less frequently. Michelin is consequently committed to developing tires for cars, bicycles, motorbikes, trucks, airplanes, etc. that perform safely throughout their working life.

Since the early days of its involvement in racing, Michelin has carved out a solid reputation on long, challenging long events like the Paris-Brest-Paris bicycle race, Gordon Bennett Cup, Le Mans 24 Hours and Paris-Dakar Rally (now known simply as the Dakar). In the past 10 years, Michelin-equipped Le Mans prototypes have succeeded in covering up to 750 kilometers on a single set of tires, at average speeds of some 240kph. That's equivalent to the distance of more than two Formula 1 grands prix!

Fewer racing tires! Michelin has long backed reducing the number of tires employed in motorsport. In the Noughties, it campaigned to cap the quantities competitors could use at rounds of the World Rally Championship. In Formula E, successive generations of its bespoke tire for the all-electric racing series allowed tire allocations per race to be cut by 25 percent. Meanwhile, the introduction of maximum tire allowances for rounds of the FIA WEC and IMSA endurance-racing championships has forced teams to run multi-stint strategies...

RENEWABLE or RECYCLED RAW MATERIALS

Making tires completely sustainable by 2050 is clearly one of the most ambitious challenges Michelin has set itself since its invention of radial technology. Michelin Motorsport's engineers, chemists and development specialists have responded by accelerating research into incorporating increasingly higher proportions of renewable or recycled raw materials into the firm's racing tires. This multi-faceted task has meant designing products that can be manufactured on a large scale while continuing to deliver the same performance levels and standards of safety as before.

We notably discovered that it was possible to extract silica from rice husk by means of a specific process. Silica increases the resilience of tire treads while reducing their rolling resistance. Since 2023, rice husk is an ingredient we use to make the tires raced by today's sophisticated Hypercar prototypes at Le Mans

Did you know that Michelin's rear MotoETM tire incorporates more than 50 percent renewable and recycled raw materials, including orange peel, pine resin and scrap tires? It is a surprise to many that tires containing orange peel can be driven in complete confidence at speeds in excess of 250kph! The proportion of renewable/recycled raw materials that go into the 2023 MICHELIN Pilot Sport slicks raced by endurance racing's Hypercar prototypes is as high as 30 percent, and 45 percent in the case of rain tires. Meanwhile, GreenGT's MissionH24 fuel-cell hydrogen endurance-racing prototype completed a parade lap of the 13.6-kilometer Le Mans circuit ahead of the 2022 Le Mans 24 Mans on Michelin tires that contained 53 percent renewable and recycled raw materials. By 2023, the proportion had reached 63 percent!

Michelin Motorsport is currently at an advanced stage with regard to research into mass-production applications and achieved significant time-savings during the development of the first road-approved rear and front tires to incorporate 58 and 45 percent renewable and recycled raw materials respectively. These figures were notably made possible thanks to the materials and supplier-reference classification work carried out by Michelin Motorsport. The technologies involved will benefit all Michelin tires by 2025.

Michelin's definition of renewable and recycled raw materials

Michelin's definition of renewable and recycled raw materials

Recycled materials: styrene recovered from polystyrene waste (yogurt pots, food trays, wrapping, etc.); textiles made from recycled PET* waste (plastic bottles, etc.); carbon black recovered from end-of-life tires.

(*) PET: Polyethylene Terephthalate

Renewable materials: responsibly-sourced rubber; butadiene (or biosourced butadiene) produced from biomass waste.

The Michelin Regen’Lab

The Michelin Regen’Lab

The Michelin Regen’Lab is a fun, instructive and interactive 3D machine that explains how new recovery technologies function. It demonstrates how styrene is recovered from yogurt pots to make synthetic rubber, for example; how monomers recovered from plastic bottles can be used to make polyester threads for tire strengthening purposes; and how carbon black is obtained from end-of-life tires to make new ones.

MODELING AND SIMULATION

When starting from a clean sheet of paper, you begin by studying the technical regulations and brief. This initial phase is followed by an exchange of data with the vehicle manufacturer to get an idea of the loads and forces the new tire will be submitted to. We then analyze these findings and simulate the forces exerted using mathematical modeling. This enables us to modify the construction and materials employed before evaluating different configurations in virtual form. The actual conception phase for a new racing tire takes around a month on the computer

After the conception phase, we analyze the forces involved, along with the tire's movements and characteristics. The data provided by the design team is applied to a modelized tire known as Tame Tire, then tested and evaluated on a simulator. This is 'driven' by one of the car's future drivers at a variety of simulated racetracks, depending on what we want to test - the construction or the compound, for example. We have an optimal correlation between the track and the simulator, which is what enables us to carry out such coherent development work virtually. The approach saves not only time and money, but also CO2 emissions.

From the virtual development phase to track-testing

The virtual development phase is followed by the production of an actual tire which is inspected and tested on a machine known as Record ahead of its first physical track run at the Ladoux Technology Center near Clermont-Ferrand, France. This extraordinary machine enables tires to be tested statically and dynamically, as if they were lapping a real circuit.

Record takes the form of a three-meter-diameter cylinder inside which a mechanical arm presses the tire against the asphalt-lined wall. It is capable of replicating different slip and camber angles at speeds of up to 350kph. The variety of running conditions it can reproduce - including wet weather – makes it possible to ensure that tires are perfectly safe before their first track run.

Tools such as these enable Michelin to simulate tire behavior in extreme conditions, making it possible to select only the most satisfactory specifications to actually produce and test going forward. Benefits of the process include fewer tires to produce, fewer test sessions to organize and fewer CO2 emissions. Although initially conceived for motorsport purposes, Record is today used widely in the development of road tires.

Canopy

Canopy

Michelin recently acquired the global lap-time simulation leader Canopy Simulation, a British specialist company that is behind one of the market's most sophisticated simulation software tools. Its cloud-based system combines circuit, car and tire models with an advanced trajectory-optimization function that simulates the input of the perfect 'virtual driver'. Humans have the final say, however, since a real driver gets the opportunity to approve the tire's final specification and the quiality of its match for the car for which it is intended.

AoTech

AoTech

Based near Paris, France, AoTech has forged a strong reputation in the world of car simulators, with customers ranging from automobile manufacturers and racing drivers, to bodies like the ACO (Automobile Club de l’Ouest). Michelin uses AoTech's dynamic platform to test its racing tires in virtual form, ahead of their actual production and on-track testing. Real-life drivers spend hours on simulators to provide their feedback on Michelin's virtual tires.

TameTire

TameTire

Michelin Motorsport conceived Tame Tire in the Noughties, at the time of its involvement in Formula 1. This thermodynamic simulation software has since evolved thanks to the combination of increasing computing power and the knowledge Michelin continues to acquire in different championships and races like the Le Mans 24 Hours.