Our vision

Michelin’s commitment to hydrogen power goes back some time. Because of the company’s unique expertise in materials and its vision of the need for more sustainable mobility, hydrogen power has been a part of Michelin for over 15 years. Currently seeking to strike a virtuous balance between human well-being, environmental protection and value creation for the company, Michelin is furthering its engagement in this area, and aims to become a world leader in hydrogen-powered systems.

Michelin is convinced that hydrogen mobility will be one of the essential components of clean mobility, complementary to electric batteries.

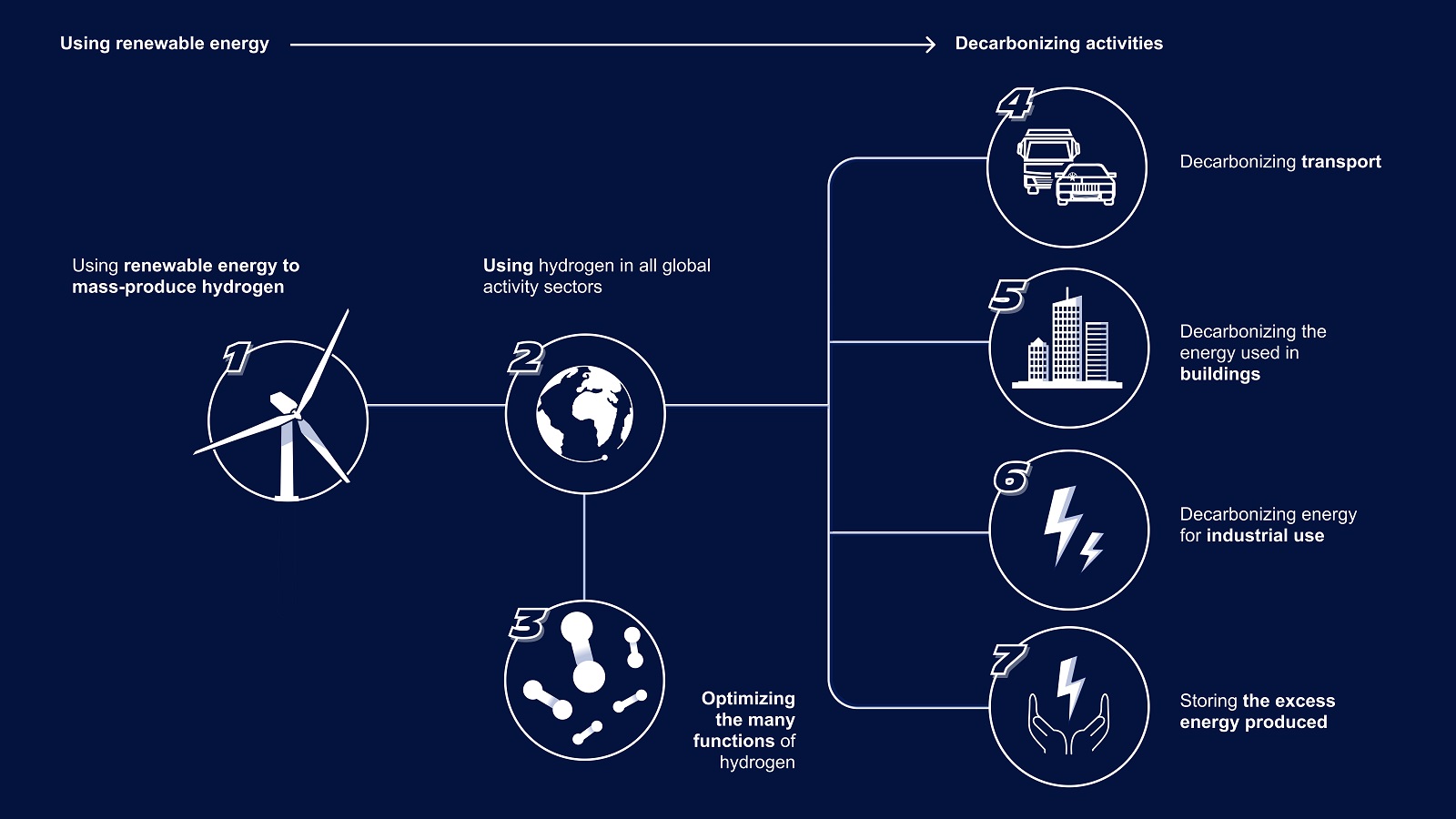

However, the advantages of hydrogen go far beyond mobility, as it represents a very interesting solution for combating CO2 emissions and air pollution. Through its flexibility of production and use, hydrogen is becoming essential to the energy transition. In particular, it will help make steel production, chemicals, district heating and of course transportation carbon free.

It is also, by far, one of the few technologies for Europe. For all these reasons, hydrogen is a strategic growth driver for Michelin. A significant share of the Group’s business will effectively be non-tire related in ten years’ time.

=

75%

of the mass of the universe

(and 92% by number

of atoms)

=

75%

of the mass of the universe

(and 92% by number of atoms)

What is hydrogen?

Where does hydrogen come from? What is it used for? What challenges does it pose for sustainable mobility and for Michelin? These are the questions we will be asking to help you find your way round this complex, but exciting subject.

________________________________________

Contrary to what we sometimes hear, hydrogen is not a “fuel”, nor even an “energy source”, it is an “energy carrier” (like electricity, incidentally). Hydrogen is a gas which can be used to store electricity and restore it on demand. But this electricity has to be manufactured, because it does not exist in a natural state (apart from in lightning bolts, but we have no way of recovering this). Hence turbines (dynamos) have to be run to make it, requiring the use of energy. Which one? That’s the question. Indeed, the environmental footprint of electricity depends on the nature of this primary energy (carbonized or not). The same is true for the vehicles that will use them.

What is hydrogen and how it is produced?

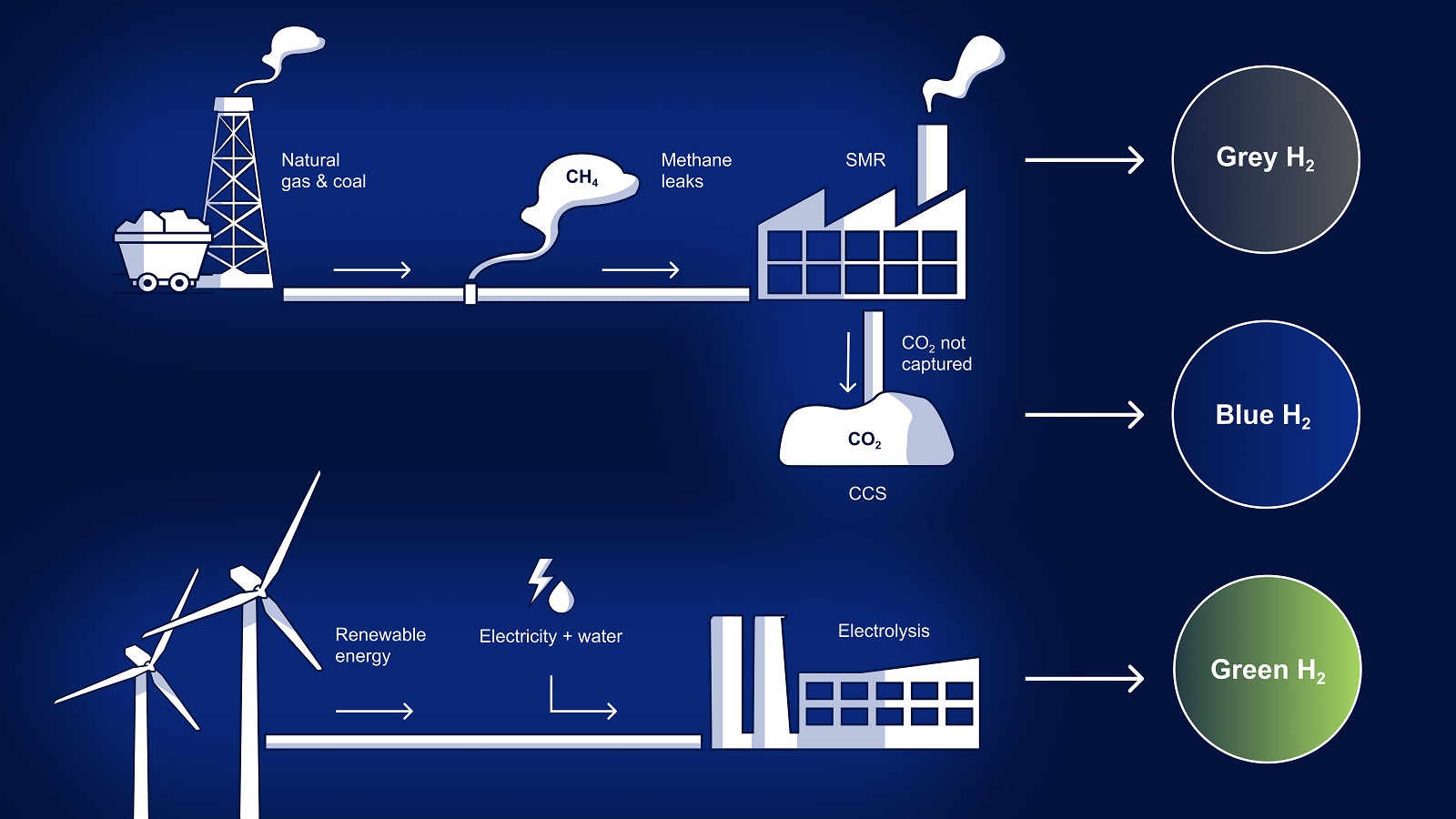

Hydrogen is the most abundant molecule in the universe: 75% of the mass of the universe, 92% of atoms. But it is rarely found on its own. Which is why dihydrogen (H2) is produced by separating it from its compound. Hydrogen is still, for the moment, highly carbonized. In other words, 90% of hydrogen is separated from its compound by means of primary energy from hydrocarbons, using the following processes:

• Steam reforming of natural gas: one molecule of methane is broken using water vapor to obtain a mixture containing hydrogen (H2) and carbon dioxide (CO2)

• Coal gasification: breakdown due to the heat from the coal into a mixture of carbon monoxide and hydrogen.

A small amount of hydrogen does however come from water electrolysis. This technology is a primary goal for Europe. It is a clean alternative, that does not release CO2: electricity “breaks” the water molecule (H2O) into dihydrogen (H2) and dioxygen (O2). This technology is green… as long as the electricity itself is produced using carbon-free energy (renewable or nuclear)!

Today, the main challenge in decarbonizing the production of hydrogen is achieving production costs that are compatible with mass usage.

Did you know?

The various names for hydrogen use different colors, depending on the energy it is produced from:

• Green hydrogen: produced from water electrolysis using electricity from renewable or nuclear sources.

• Blue hydrogen: produced from natural gas, combined with CCUS* technology. The CO2 released is captured, either stored permanently (CCS*) or re-used in an environmentally-responsible manner (CCU*).

• Grey hydrogen: produced from fossil fuels without using either CCUS or CCS technology.

• Black hydrogen: produced from coal.

* CCUS: Carbon Capture, Utilization and Storage/Carbon footprint reduction technique which re-uses the CO2 as an input in industry (CCU) or by storing it underground (CCS)

How is hydrogen used?

Since the beginning of the space industry, hydrogen has played an important role in storing the energy needed by rockets. Even now, liquid hydrogen is still used to launch the European Ariane 5 rocket. Nowadays, hydrogen mainly has industrial applications (more than 90%):

• In the chemical industry, to produce ammonia (fertilizer) and methanol

• To refine petroleum products

• To produce steel

And tomorrow?

52,000 light vehicles,

powered by hyfrogen were on the road worldwide, supplied by a network of 729

refueling stations

How does a hydrogen-powered vehicle work?

Firstly, it’s important to know that hydrogen is a very light gas that takes up a lot of space at atmospheric pressure. For ease of transportation, it needs to be reduced in volume, and there are several techniques for doing this. In particular, high-pressure storage in the form of a gas, in controlled conditions in FCEV* vehicles, or even storage at very low temperature, in liquid form (industrial applications).

A hydrogen-powered vehicle’s engine is in fact an electric motor (just like in a battery vehicle), powered by electricity produced from an onboard hydrogen fuel cell. By recombining the oxygen in the air and the hydrogen stored in the tank, the fuel cell extracts the electricity with which the hydrogen is charged. Compressed to 700 bar, 1 kg of hydrogen releases almost 3 times more energy than 1 kg of gasoline and only water is discharged from the vehicle.

Not only is hydrogen mobility contributing to a reduction in greenhouse gas emissions, it is also helping to improve air quality in city centers.

*FCEV: Fuel Cell Electric Vehicle

Is a hydrogen-powered vehicle an electric vehicle?

Yes, a hydrogen-powered vehicle (FCEV) and a battery electric vehicle (BEV*) are much the same thing. The two technologies coexist and are complementary depending on the application. BEVs have been in use for many years, whereas FCEVs are currently being rolled out. The only difference is the way the energy is stored onboard: in a conventional battery or in a tank of hydrogen charged with electricity. A hydrogen-powered vehicle is in summary an electric vehicle with autonomous electricity generation.

They have a number of advantages in common: no local emissions of CO2, no particles or pollutants from tank to wheel, silence, ease of use, etc.

Hydrogen’s plus point is that it offers similar refueling times to a vehicle with a fossil fuel combustion engine… as long as the network of hydrogen stations is sufficient, which is a whole other question!

Key figures concerning the global market for hydrogen-powered vehicles:

• 2019: 16,000 light vehicles, 1,600 heavy vehicles powered by hydrogen were on the road worldwide, supplied by a network of 407 refueling stations

• Between now and 2030 (Michelin estimate): 2 million vehicles fitted with a hydrogen fuel cell (80% of light vehicles and 20% of heavy vehicles and buses)

*BEV: Battery Electric Vehicle

What challenges does the hydrogen-powered vehicle still face?

There are many. The first is the economic challenge. This lies in the sector’s ability to switch from small-scale production (the laboratory) to mass production. The volume effect will be very significant once more than 10,000 vehicles a year are being produced.

This is why hydrogen's future is closely correlated to member States’ ambitions in terms of the climate and energy use. Much will depend on the national strategies put in place and programs of grants to help ease the switch (scale up) to hydrogen mobility, both in terms of the infrastructure (refueling stations) and vehicles, or even the cost of this energy.

The specific challenge of hydrogen road transport

Géraud Pellat de Villedon,

Head of CSR for the supply chain, Michelin

“Deploying hydrogen logistics requires the creation of local ecosystems”

Interview of Géraud Pellat de Villedon

Does hydrogen have a future in transport logistics?

It certainly has a role to play in the energy mix of a carbon-free supply chain. This nascent technology still includes a lot of unknowns. And, it must be said, hydrogen transport is currently still at a totally embryonic stage.

What is preventing the explosion in this market?

It comes down to market forces. For starters, there are no trucks. Why? Because hydrogen is a very expensive technology and testing even the smallest prototype costs around €1m. The only economically feasible prospect for increasing production currently involves retrofitting. The only problem is that transport companies are not necessarily ready to pay €400,000 for vehicles that have already been on the road for four to five years. Another obstacle is that these same companies will not launch into hydrogen unless they can be guaranteed of being able to refuel their fleet from a variety of distribution chains. Yet energy companies are reluctant to install filling stations close to any competition. Finally, like all nascent markets, hydrogen logistics is a prisoner of the “chicken and egg” syndrome: on the one hand, no-one wants to build a filling station until there are enough vehicles, while on the other, no-one wants to commit to trucks if there are no filling stations. In short, everyone defends their interests, which is quite logical. But that creates a lot of inertia.

So, what can be done?

All the players in the sector need to work to build models and define conditions that will make it possible to produce low-cost solutions. At Michelin, we have identified two key trigger points which we believe will enable the model to be rolled out on a large scale: succeeding in producing trucks for less than €350,000 (i.e. two to three times cheaper than today); lowering the price of hydrogen at the pump to €5/kg (compared to €10 to €12 at present). If we can reach these thresholds by 2027, we are prepared to bear the additional cost of the technology for a certain time. We already aim to roll out several dozen trucks by 2025.

But this roll-out requires collective consideration and commitment across the entire sector...

The solution lies in compromise. This is in everyone’s interest, because no one will be able to bring hydrogen to an industrial level on their own. This is the whole point of Supply Chain 4 Good, a community of 50 members set up by France Supply Chain to design and trial innovative solutions to facilitate sustainable logistics. We already know that the key to low-carbon hydrogen transport lies in the creation of public ecosystems bringing together four key groups: energy suppliers, truck manufacturers, trucking companies and maintenance companies. These ecosystems, which do not currently exist, must be designed as clearly identified networks within well-defined areas. The use of hydrogen trucks for long-haul journeys across Europe is a target we have set for 2030. To achieve this, we need to step up the number of roll-outs at local level, to then be extended at regional and then national level.

10 to 15 millions vehicles fitted with a hydrogen fuel cell (70% of light vehicles and 30% of heavy vehicles and buses)

(Michelin estimate)

Milestones of Michelin's hydrogen story

2004: Hy-Light

In 2004 Michelin unveiled the Hy-Light. Designed in Switzerland by Michelin Research and Technology (MRT) in conjunction with the Paul Scherrer Institute (PSI), this vehicle featured two major innovations: a novel electric motorized wheel concept - the Active Wheel - and a fuel cell to generate the electricity required to power the motors housed in the wheels.

2007: Hy-Light 2

Three years later, a new improved version of the 2004 Hy-Light was released - the Hy-Light 2. It was based on the same principle and structure incorporating a fuel cell entirely developed by the MRT advanced research teams. This four-seater weighed as little as 790 kg and boasted a 400-km range.

_____________________________________________________________________

2008: Airbus

An Airbus airliner successfully completed a flight using a fuel cell to power the ancillary circuits - a first! The 20-kW fuel cell supplied an electric motor, the hydraulic circuit backup system and the aileron motors. The fuel cell performed well during the flight across a wide range of load factors.

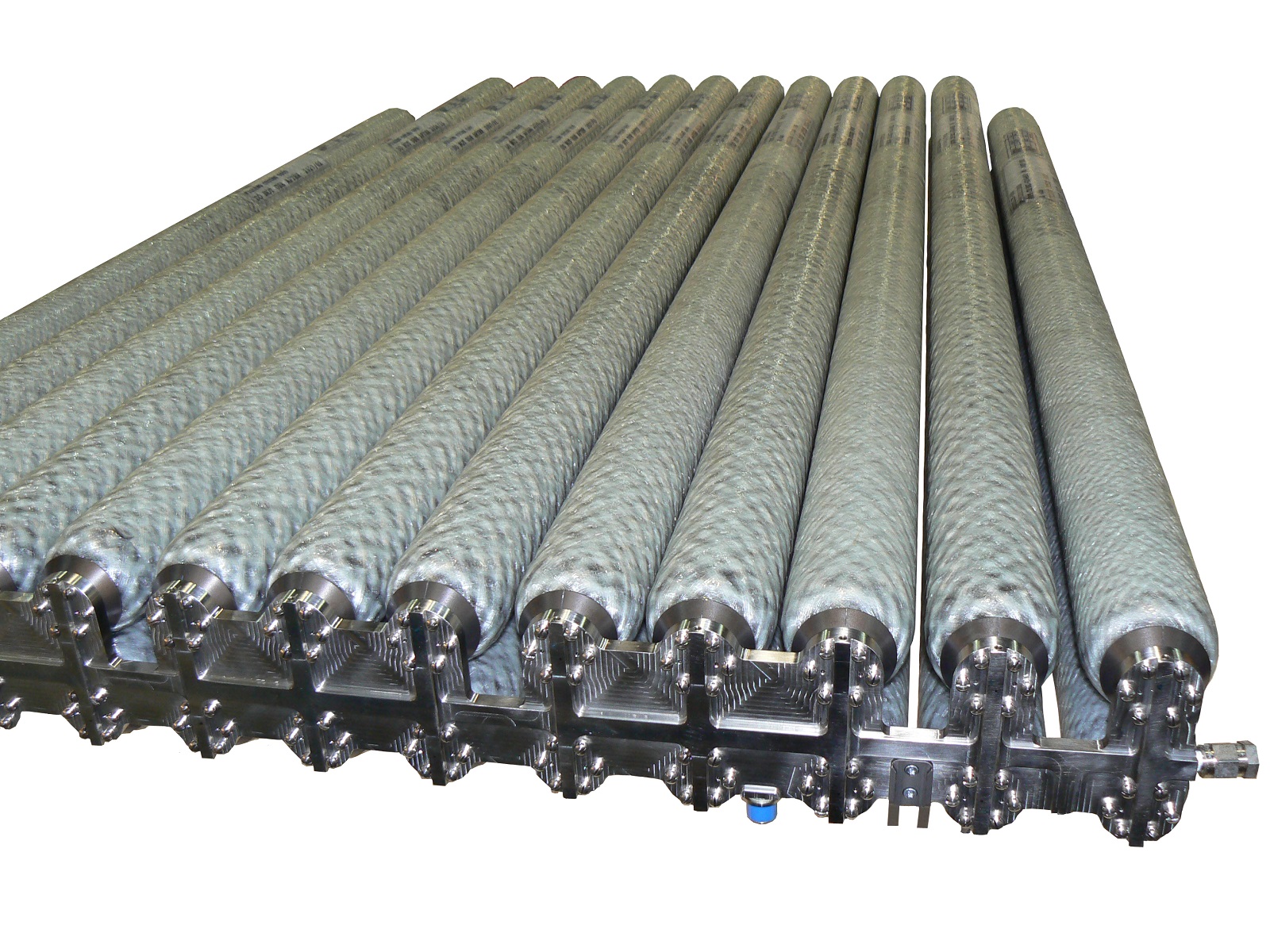

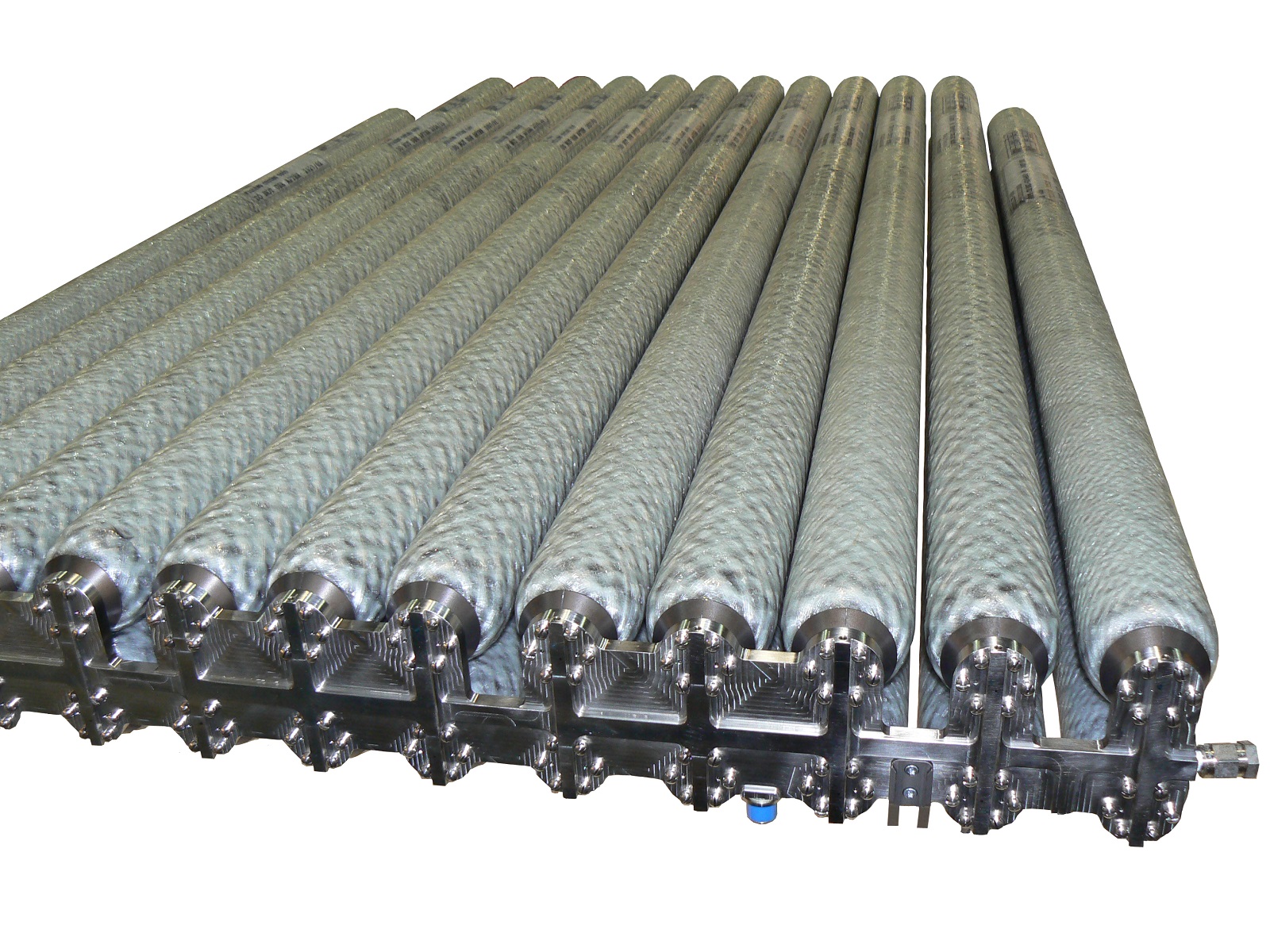

2010: Hydrogen tanks

In 2010 Michelin kicked off its development of type 4 hydrogen tanks. These are capable of storing hydrogen at a pressure of 700 bars which means between 6 to 7 kg of hydrogen can be carried on board. The hydrogen tanks are wrapped in multiple layers of reinforced carbon fiber.

2011: FCity-H₂

The F-City H2 is an urban vehicle developed jointly in 2011 by FAM, a French company based in Franche-Comté and Michelin. The electricity which drives the F-City H2 comes from a fuel cell powered by gaseous hydrogen. Both lightweight and compact, the unit supplied by Michelin consists of a 4-kW fuel cell and a tank containing 1 kg of hydrogen at a pressure of 350 bars.

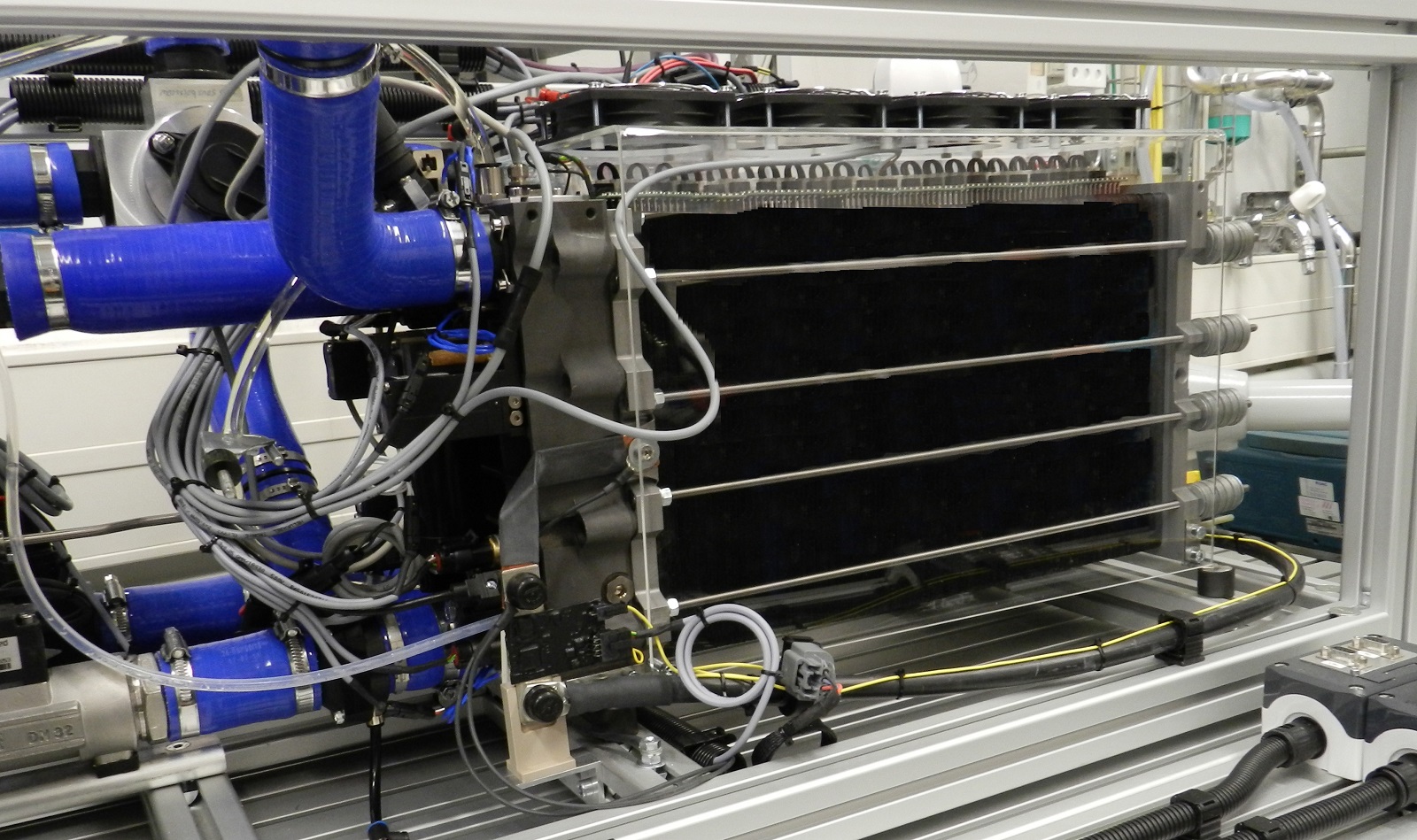

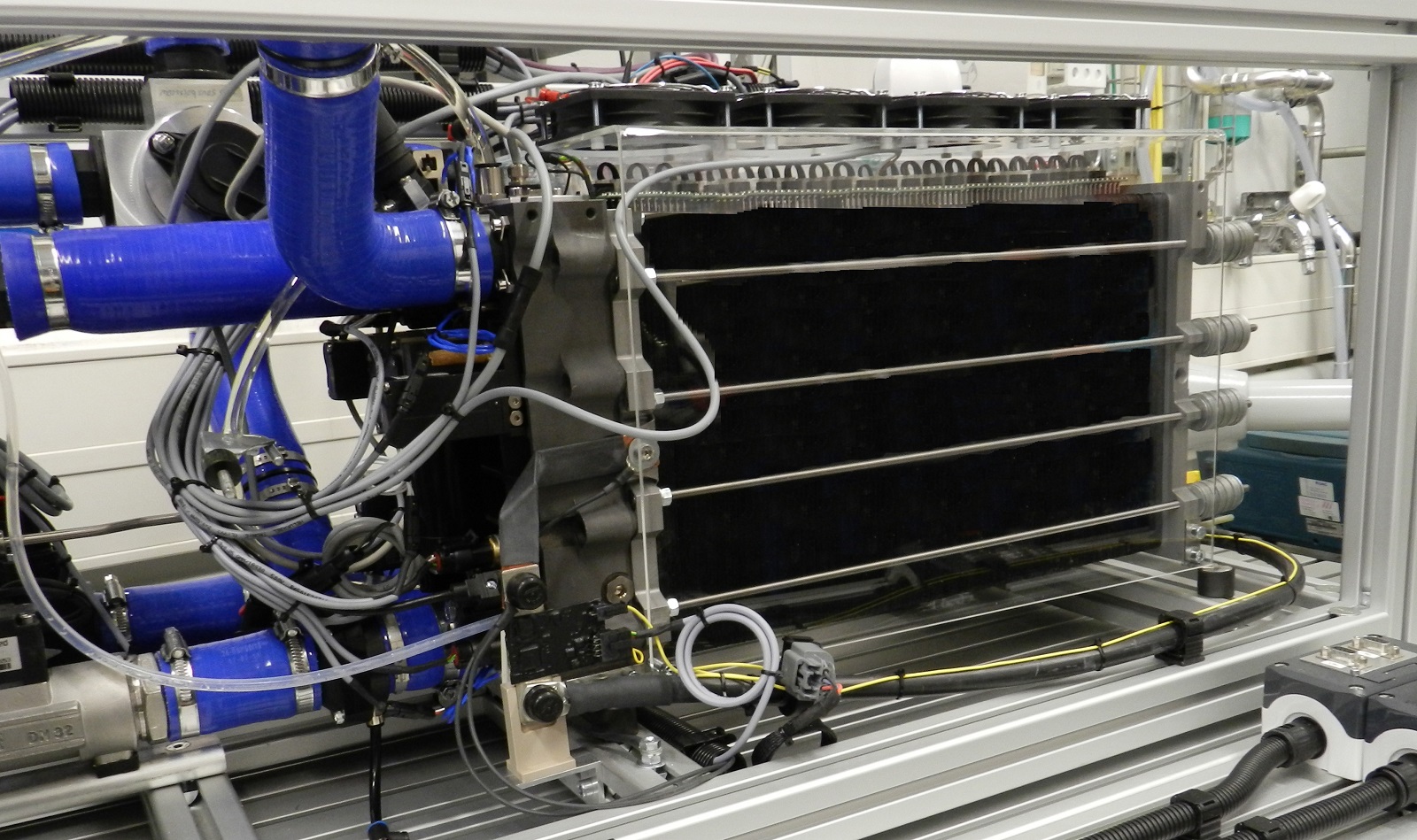

2014: Fuel cell

A new milestone was reached with the development of a H2/Air fuel cell with a 50-kW power rating. This tough, powerful and compact fuel cell was now ready to be installed on many different types of vehicle.

2015 / 2016: RENAULT Kangoo

Renault fitted a Symbio fuel cell to a fleet of 200 Kangoo vans. It proved its worth, successfully extending the vehicle range. The Kangoo ZE Hydrogen was the first utility vehicle in Europe to be equipped with a fuel cell. This principle offered an appropriate response to the concerns of certain Kangoo ZE users.

2017: HyPort

In 2017 Toulouse-Blagnac airport adopted the HyPort project with backing from the French energy transition agency ADEME. The idea was to produce and distribute hydrogen for use by vehicles traveling around the airport such as ground handling vehicles and terminal transfer buses. The hydrogen was also available for private cars.

________________________________________________________________________________________________

2007: YeloH₂

Hydrogen is also an excellent solution for marine transport such as the Yelo H2 electric sea bus which makes use of a fuel cell as a range extender. Containing four tanks with a combined capacity of 7 kg of hydrogen together with a 12 kW Michelin fuel cell, it was the first fuel cell powered vehicle to travel on the sea.

2018: Safra Businova

Safra’s Businova H2 was the first fuel cell powered bus made in France. It contained a 250-kW electric engine and 132-kWh battery pack together with a 30-kW Symbio fuel cell. Power is supplied from tanks which can contain as much as 30 kg of hydrogen at a pressure of 350 bars representing a range of at least 350 km.

2019: Symbio

In November 2019, Michelin and Faurecia set up “Symbio, a Faurecia Michelin Hydrogen Company.” This joint venture encompasses all Michelin’s hydrogen fuel cell related activities - including its subsidiary Symbio - and those of Faurecia. This new entity aims to capture a 12% market share and reap revenue in the region of €1.5 billion in 2030.

They tell the story

From concept to innovation

Pierre Varennes, former Michelin Technical and Research & Development Director, explains what sparked Michelin’s interest in hydrogen fuel cells back in 2003.

The story behind the technology

Valérie Bouillon Delporte, Michelin hydrogen ecosystem director and President of Hydrogen Europe, explains Michelin's commitment to zero-emission mobility in French, European and global ecosystems.

=

3 to 5 minutes

=

3 to 5 minutes

Hydrogen, how does it work?

What is a hydrogen-powered vehicle?

An electric vehicle equipped with a hydrogen battery provides similar usage conditions to a conventional vehicle, while strongly reducing environmental impact. It has a comparable range (between 500 and 600km) and takes only a few minutes to charge in a special station.

As a result, hydrogen technology overcomes two of the main disadvantages of the use of battery-powered electric vehicles: limited range and recharging time.

Hydrogen: driving strategic growth for Michelin

Maude Portigliatti,

Business Director, High-Tech Materials and member of the Group Executive Committee, Maude Portigliatti looks at Michelin’s commitment and long-term ambitions in hydrogen.

Hydrogen: driving strategic growth for Michelin

What role does hydrogen play in the Michelin strategy?

M.P: Hydrogen represents one of the long-term growth levers for Michelin in High-Tech Materials, along with 3D metal printing, sustainable flexible composites and biocompatible materials for regenerative medicine and cellular therapy. In the next ten years, 20% to 30% of our Group activity will come from "beyond tires".

Is this a recent commitment?

M.P: Our commitment to hydrogen is not recent. Our expertise in materials, along with the need to promote sustainable mobility, motivated us to become players in this sector over 15 years ago. We remain convinced that hydrogen mobility will be an essential component of clean transport, in addition to batteries. Hydrogen is the most comprehensive solution for reducing CO2 emissions, air pollution and encouraging the transition to fossil-free energy sources. The context is promising: the announcement of "Hydrogen Strategy France", that echoes the European strategy published in July 2020, constitutes a crucial step for the development of a first-rate French hydrogen industry.

How did you develop your hydrogen strategy?

M.P: Our strategy is built on three cornerstones. One of our aims is to become a world leader in hydrogen mobility systems. Creating the joint-venture Symbio with the automotive supplier Faurecia in November 2019 was a key step towards achieving this goal.

Our joint-venture has already been successful, as shown by the recent signature off a contract concerning the development of 1,500 buses by the French company Safra or again Symbio being chosen by Stellantis to accompany their first hydrogen-powered commercial vehicles.

In 2022, we also began the construction of one of the biggest fuel cell plants in Europe, with production planned to start in 2023.

Symbio is therefore well on track to reach its target of 200 million euros turnover in 2025 and 12% market share and 1.5 billion euros turnover by 2030.

Could you tell us more about the other strategic pillars in terms of hydrogen?

M.P: We also want to develop hydrogen mobility on a regional scale, by rolling out vehicles and infrastructure at the same time. Our commitment can be seen in the "Zero Emission Valley" (ZEV) project, the result of a public-private partnership with the Auvergne-Rhône-Alpes region, Michelin and the Engie Group. This project embodies a clean mobility offer on a regional scale, to make it the leading hydrogen mobility zone in Europe. Between now and the end of 2023, the ZEV project plans to set up 20 green hydrogen charging stations and develop 1,200 hydrogen vehicles for professionals.

Yet this project is just the first step, lessons learned from it will enable us to reproduce the model in other regions of France and beyond.

How would you define your goals in Motorsport, your last strategic driver?

Michelin has always seen motorsport as a laboratory for innovation and a technical showcase.

Today, our aim is to accelerate the roll out of hydrogen mobility in motorsport. With this in mind, in June 2020 Michelin and its subsidiary Symbio became key partners in Mission H24, a project specifically designed to introduce hydrogen technology in endurance vehicles competing in the Le Mans 24 Hours. To reach this objective, engineering laboratory GreenGT has developed a new type of car the "Le Mans Prototype" (LMP), equipped with hydrogen-electric propulsion and a high power Symbio battery. By working in close collaboration with the racing team, Symbio will fast gain valuable experience in high power hydrogen batteries. Michelin is lending its tire expertise to meet this new challenge. Information gathered on the circuit will speed up research and development.

The benefits of Hydrogen for carbon-free mobility

Yves Faurisson

Directeur des activités Hydrogène de Michelin

Retour sur l’engagement précoce du Groupe et sur les avantages de l’hydrogène pour une mobilité décarbonée.

The advantages of hydrogen no longer remain to be proven even though this area of research was slow to get going

Quels sont les grands attraits de l’hydrogène aujourd’hui ?

L'hydrogène est sur toutes les lèvres et pour cause : capable de stocker l’électricité et de la restituer à volonté, sans émettre de polluants, il contribue de plus à la réduction des gaz à effet de serre lorsqu’il est produit par électrolyse à partir d’énergies renouvelables. Un véhicule équipé d’une pile à hydrogène a l’avantage de se recharger rapidement (3 à 5 mn pour un véhicule de tourisme) et d’offrir une autonomie compatible avec les usages les plus intensifs, notamment ceux de la mobilité lourde. De sérieux atouts, qui font de l’hydrogène l’une des solutions pour sortir de notre dépendance aux carburants fossiles.

Depuis quand Michelin s’intéresse-t-il à l’hydrogène ?

Michelin a réalisé l’intérêt de cette technologie il y a 20 ans. Au début des années 2000, le débat sur la réduction des émissions de CO2 ne faisait que commencer et l'électrification des véhicules n'en était qu'à ses balbutiements. À cette époque, les dirigeants de Michelin envisageaient déjà l'ère de la mobilité sans émission, un concept largement développé au cours des sommets de la mobilité durable Michelin Challenge Bibendum, devenus Movin'On. Très tôt, Michelin a compris que l'hydrogène pourrait jouer un rôle majeur dans la transition vers l'abandon des combustibles fossiles.

Au-delà de Michelin, est-ce que d’autres ont aussi conscience de ces enjeux ?

De nombreux pays ont des ambitions en matière d'hydrogène. L’Europe a présenté son plan stratégique pour l’hydrogène en juillet 2020. L’Allemagne, puis la France, lui ont emboîté le pas avec des plans de grande ampleur (9 et 7 milliards d’euros), en septembre 2020. En France, il doit permettre de devenir un acteur mondial majeur à l’horizon 2030. Tous les grands constructeurs de voitures, de camions, de véhicules utilitaires légers et d'autobus ont maintenant lancé des programmes hydrogène. Au-delà des véhicules routiers, de nombreux programmes ont également été lancés dans les secteurs de la marine, des chemins de fer, de l'aviation, de la manutention et des mines. En 2030, on estime que les revenus globaux de l'hydrogène pourraient atteindre environ 300 milliards de dollars US. Dans cette chaîne de valeur, la production d'hydrogène et les applications finales de transport sont estimées à environ 60 milliards de dollars. En somme, l’hydrogène constitue une solution avantageuse, pour répondre aux enjeux de la transition énergétique, mais aussi sur le plan économique. Pour Michelin, il représente l’un des leviers de croissance majeurs du Groupe à horizon 2030.

25%

of world CO2

emissions

of world's CO2

emissions

Bringing together all the links in the value chain

Michelin, leading player in hydrogen mobility

The idea of hydrogen mobility, long ahead of its time, is fast becoming a reality. Today Michelin plans to implement it, building on its Symbio subsidiary, the strength of its performance at the Le Mans 24 Hours and a fast-developing ecosystem. Michelin is a major player in the hydrogen mobility sector, in France and Europe, and has been for many years. Through its commitment to more ...

Bringing together all the links in the value chain

The idea of hydrogen mobility, long ahead of its time, is fast becoming a reality. Today Michelin plans to implement it, building on its Symbio subsidiary, the strength of its performance at the Le Mans 24 Hours and a fast-developing ecosystem.

Michelin is a major player in the hydrogen mobility sector, in France and Europe, and has been for many years. Through its commitment to more sustainable mobility and its unique knowledge and expertise in the field of high-tech materials, Michelin is ideally placed to

become one of the leading global players in the international fuel cell industry. « The longrange Michelin view on hydrogen mobility, is firstly zero-emission mobility that meets the needs of both the transport industry and individuals” says Yves Faurisson, Head of Hydrogen Activities at Michelin.

Mobility provided by an electric vehicle equipped with a fuel cell also helps to improve air quality, especially in large urban areas, as these vehicles emit no pollutants during use.

An efficient partnership with Faurecia

Michelin’s motivation to take part in the development of the car of the future lead it along the hydrogen road almost 20 years ago. Today, searching for the right balance between individual’s well-being, environmental protection and creating added value for the group, Michelin confirms its involvement in the field and aims to become, through Symbio (joint venture between Michelin and Faurecia), one of the leaders in hydrogen systems with target sales of around 1,5 billion euros between now and 2030. Michelin and Faurecia share the same objective to become the world leader in hydrogen-mobility systems, thanks to the combined assets of both groups. An initial investment of 140 million euros will allow for construction in France of a first European production site in Saint Fons, south of Lyon. The plant will create hundreds of jobs.

The exemplary standards of motorsport

When it comes to learning, the Michelin group has always looked to motorsport where high standards provide the ideal context for testing innovations in extreme conditions. The group’s hydrogen mobility solutions are no exception to the rule. So, in June 2020, the

Michelin group and Symbio became partners of reference for Mission H24. This project aims to introduce hydrogen-mobility technology in endurance racing vehicles competing in the Le Mans 24 Hours in 2024. That’s why Green GT, a Swiss engineering company, has developed a car equipped with a hydrogen-electric engine (Symbio battery) that meets the Le Mans 24

Hours regulatory requirements. Christened LMPH2G, this prototype will be enlisted in the race by the H24Racing team. Working in close collaboration with this team, Symbio will fast gain valuable experience in high-powered hydrogen batteries.

For its part, Michelin will lend its tire expertise to these new needs. Information gathered this way on the circuit will help to speed up research and development. Lastly, Michelin and Symbio will share their respective expertise with the competent motorsport bodies and

participate in defining technical regulations for future races with hydrogen-powered cars.

Creating accessible and sustainable hydrogen mobility

Hydrogen mobility does not rely simply on the vehicles. Hydrogen recharging facilities need to progress at the same speed as vehicles become available. To ensure a sufficient network of recharging stations, provide accessible mobility and roll it out across all types of transport, industrial and institutional players end-to-end of the value chain need to be mobilized. A clear example of Michelin’s strong commitment is the « Zero Emission Valley » (ZEV) project. Created by the Auvergne-Rhône-Alpes region and the Engie group, the ZEV project deploys a clean mobility offer on a regional scale.

The project plans to install twenty green hydrogen charging stations and roll out 1200 hydrogen-powered vehicles for professionals. The special stations will be located in big urban conurbations to enable vehicle fleets to conduct their business with the same range as

conventional vehicles. To deploy the ZEV project, Michelin has become a shareholder in the Hympulsion company, responsible for installing and running the 20 stations along with Engie, the Auvergne-Rhône-Alpes region, the Caisse des Dépôts and Crédit-Agricole.

Bringing together all the links in the value chain

Michelin, leading player in hydrogen mobility

The idea of hydrogen mobility, long ahead of its time, is fast becoming a reality. Today Michelin plans to implement it, building on its Symbio subsidiary, the strength of its performance at the Le Mans 24 Hours and a fast-developing ecosystem. Michelin is a major player in the hydrogen mobility sector, in France and Europe, and has been for many years. Through its commitment to more ..

Bringing together all the links in the value chain

The idea of hydrogen mobility, long ahead of its time, is fast becoming a reality. Today Michelin plans to implement it, building on its Symbio subsidiary, the strength of its performance at the Le Mans 24 Hours and a fast-developing ecosystem.

Michelin is a major player in the hydrogen mobility sector, in France and Europe, and has been for many years. Through its commitment to more sustainable mobility and its unique knowledge and expertise in the field of high-tech materials, Michelin is ideally placed to

become one of the leading global players in the international fuel cell industry. « The longrange Michelin view on hydrogen mobility, is firstly zero-emission mobility that meets the needs of both the transport industry and individuals” says Yves Faurisson, Head of Hydrogen Activities at Michelin.

Mobility provided by an electric vehicle equipped with a fuel cell also helps to improve air quality, especially in large urban areas, as these vehicles emit no pollutants during use.

An efficient partnership with Faurecia

Michelin’s motivation to take part in the development of the car of the future lead it along the hydrogen road almost 20 years ago. Today, searching for the right balance between individual’s well-being, environmental protection and creating added value for the group, Michelin confirms its involvement in the field and aims to become, through Symbio (joint venture between Michelin and Faurecia), one of the leaders in hydrogen systems with target sales of around 1,5 billion euros between now and 2030. Michelin and Faurecia share the same objective to become the world leader in hydrogen-mobility systems, thanks to the combined assets of both groups. An initial investment of 140 million euros will allow for construction in France of a first European production site in Saint Fons, south of Lyon. The plant will create hundreds of jobs.

The exemplary standards of motorsport

When it comes to learning, the Michelin group has always looked to motorsport where high standards provide the ideal context for testing innovations in extreme conditions. The group’s hydrogen mobility solutions are no exception to the rule. So, in June 2020, the

Michelin group and Symbio became partners of reference for Mission H24. This project aims to introduce hydrogen-mobility technology in endurance racing vehicles competing in the Le Mans 24 Hours in 2024. That’s why Green GT, a Swiss engineering company, has developed a car equipped with a hydrogen-electric engine (Symbio battery) that meets the Le Mans 24

Hours regulatory requirements. Christened LMPH2G, this prototype will be enlisted in the race by the H24Racing team. Working in close collaboration with this team, Symbio will fast gain valuable experience in high-powered hydrogen batteries.

For its part, Michelin will lend its tire expertise to these new needs. Information gathered this way on the circuit will help to speed up research and development. Lastly, Michelin and Symbio will share their respective expertise with the competent motorsport bodies and

participate in defining technical regulations for future races with hydrogen-powered cars.

Creating accessible and sustainable hydrogen mobility

Hydrogen mobility does not rely simply on the vehicles. Hydrogen recharging facilities need to progress at the same speed as vehicles become available. To ensure a sufficient network of recharging stations, provide accessible mobility and roll it out across all types of transport, industrial and institutional players end-to-end of the value chain need to be mobilized. A clear example of Michelin’s strong commitment is the « Zero Emission Valley » (ZEV) project. Created by the Auvergne-Rhône-Alpes region and the Engie group, the ZEV project deploys a clean mobility offer on a regional scale.

The project plans to install twenty green hydrogen charging stations and roll out 1200 hydrogen-powered vehicles for professionals. The special stations will be located in big urban conurbations to enable vehicle fleets to conduct their business with the same range as

conventional vehicles. To deploy the ZEV project, Michelin has become a shareholder in the Hympulsion company, responsible for installing and running the 20 stations along with Engie, the Auvergne-Rhône-Alpes region, the Caisse des Dépôts and Crédit-Agricole.

Michelin and Symbio: making hydrogen mobility accessible to all

Philippe Rosier

CEO of Symbio

Yves Faurisson

Michelin Hydrogen Activities Director

When it comes to hydrogen mobility, Michelin and Symbio share the same vision and objectives: to provide freedom of movement without emission of pollutants and CO₂. Yves Faurisson, Director of Hydrogen Activities at Michelin and Philippe Rosier, CEO of Symbio tell us more.

Michelin and Symbio: making hydrogen mobility accessible to all

What is your vision for hydrogen mobility?

Yves Faurisson: Michelin’s vision for hydrogen mobility, is first and foremost one of zero-emission mobility which has now become a prerequisite. This trend is well under way in transport industries. But in addition to battery electric vehicles, we need to find another solution to cover all usage modes.

Philippe Rosier: For Symbio our vision of hydrogen mobility is all about a giant step towards a carbon neutral world. For beyond the various measures to encourage energy transition in the transport sector, this is the only technology, complementary to that of the battery, that can really help zero-emission mobility take off. Professionals, who have a heavy use of their vehicles, will show the way.

What strong points and expertise will you use?

Y.F.: The strong point of our approach, is precisely Michelin’s experience in the field of hydrogen. This dates back to 2004, well before everyone became interested. Hydrogen at Michelin is based on long-acquired knowledge, and on the group’s expertise in high-tech materials. We’ve taken the time to look at, validate and think through the industrialization of these solutions. Today, this expertise and these convictions can be found at the heart of Symbio. As a result, the Michelin group, key player in mobility, plays a key role in bringing together the companies, regions and countries engaged alongside it.

P.R.: Symbio is a renowned leader in the development of efficient, compact hydrogen systems adapted to constructor needs, over a wide range of vehicles – light commercial utilities, buses, trucks, SUV, etc. This is the result of over ten years’ experience, sound “automobile” expertise and the 4 million kilometers covered by vehicles we’ve already equipped!

What’s more, right behind us are our shareholders Michelin and Faurecia, with whom we’ve developed an ambitious strategy. This builds on our key asset: our 350 Symbio partners.

What can you tell us about your ongoing projects?

Y.F.: We’re continuing to invest in and support Symbio in its internationalization. Symbio continues to make progress by drawing on the dual expertise of Michelin and Faurecia. And the first results are already clear to see, for example the Stellantis group has chosen Symbio technology for its future fuel cell vehicles. In 2022, we placed the foundation stone of the Symbio plant in Saint-Fons with an aim to start production in 2023.

Furthermore, the "ecosystem construction" phase continues to move along with the installation of special hydrogen charging stations and electrolyzers capable of producing green hydrogen in the context of the "Zero Emission Valley" project, implemented by the Auvergne-Rhône-Alpes region.

P.R.: As you can imagine, we have several projects on the go – which we will leave our automaker customers to reveal. Our publicly known projects are those with Stellantis (utility vehicle) and with Safra (1,500 buses). We are also equipping the first hydrogen race car, for the H24 Racing team, that will compete at Le Mans 24 Hours in 2025.

What are your market predictions and Symbio’s aspirations?

Y.F.: We believe that by 2030, the market will have reached 2 million passenger cars and light commercial utility vehicles, to which 500,000 heavy goods vehicles, coaches and buses can be added. Hydrogen-powered transport responds well to the needs of heavy goods vehicles, whereas battery electric solutions require using one third of load capacity. This is why all the major players in heavy goods vehicles have already started to work in the hydrogen sector. This being said, in volume terms, the key market remains passenger cars. With plans to reach 12% market share in hydrogen systems with a turnover of 1,5 billion euros Symbio would be up among the leaders.

P.R.: Clearly, the market exists and is growing fast. The first sectors to become accessible will be light commercial utility vehicles and buses, followed by trucks. Installing special hydrogen charging stations for these three sectors would allow hydrogen to take off in passenger cars by 2030. Symbio aims to supply the entire market and indeed to become an industry leader by producing 200,000 hydrogen systems a year by then.

3 initiatives serving the Group’s vision

Symbio

By the end of 2021, three Stellantis brands, Peugeot, Citroën and Opel, will offer light commercial vehicles equipped with Symbio fuel cells. Looking back over a successful partnership, complemented by the Safra adventure.SYMBIO and Stellantis : a shared future to advance hydrogen mobility?

SYMBIO, a major hydrogen fuel cell player owned 50/50 by Michelin and Faurecia, is currently in exclusive negotiations with Stellantis, which wants to acquire a stake in the company. SYMBIO and Stellantis have already had a strategic partnership for several years. Let's take a look back at the key steps in this partnership between two French hydrogen mobility leaders.

The partnership between SYMBIO and Stellantis already has a solid history. The two companies have been working together for the past four years to develop hydrogen-powered electric light commercial vehicles (LCVs) in response to the expectations of professionals who are committed to the energy transition. In 2021, Stellantis announced the launch of hydrogen versions of the Peugeot Expert and Citroën Jumpy, which are designed for intensive use and offer a long range, fast recharging, and zero emissions. SYMBIO provides these vehicles with a compact hydrogen fuel cell system that meets the automotive industry's strict quality and reliability standards.

“At SYMBIO, we see this strategic partnership not only as clear recognition of just how robust our solution is, but also of our abilities in production and innovation as a Group”, says SYMBIO CEO Philippe Rosier. “It's an honour for us to be associated with one of the world's very first mass-production initiatives to offer a promising form of future mobility that delivers zero CO2 emission without compromising on performance”.

SYMBIO works with other clean hydrogen mobility pioneers like SAFRA as part of a strategic partnership for the introduction of hydrogen-powered buses. Businova buses, which are already operational in several French cities, symbolise the need for continued development of hydrogen technologies, as the market awaits the arrival of new-generation Hycity buses.

SYMBIO takes its ecosystem to a new level and secures its supplies of green hydrogen

Following the recent announcement of the Innoplate joint venture between SYMBIO and Schaeffler for the large-scale production of metallic bipolar plates—a vital component of hydrogen fuel cells—SYMBIO has now announced its signature of a Letter of Intent (LOI) with the Compagnie Nationale du Rhône (CNR) and ENGIE. This agreement will secure the green hydrogen needs of SymphonHy, the Giga Factory in Saint-Fons, which is one of Europe's biggest hydrogen fuel cell production sites.

MissionH24

The aim of MissionH24 is to race a hydrogen-powered electric car in the Le Mans 24 Hours. Michelin, through its Symbio subsidiary, is a key player in the project.MissionH24: mobility for tomorrow

The aim of MissionH24 is to run a hydrogen-powered electric car in the Le Mans 24 Hours. Michelin, through its Symbio subsidiary, is a key player in the project.

Since the earliest phases, Michelin has been involved in motor racing with its tires. Naturally, the idea of being involved in a project with an electric race car equipped with a fuel cell appealed to the group. This is how Michelin became one of the key partners in MissionH24, a project founded by the Automobile de l’Ouest Club (Western France Automobile Club), organizer of Le Mans 24 Hours and Swiss engineering laboratory GreenGT. The objective is to have hydrogen-powered electric vehicles competing in the Le Mans 24 Hours by 2025. With this in view, experts from the Michelin group are currently working on developing a vehicle with the H24 racing team. Michelin and Symbio (joint-venture between Michelin and Faurecia) are sharing their expertise with motor racing authorities to help define new technical regulations for future races reserved for hydrogen-powered vehicles.

Preparing tomorrow’s mobility

Chairman of the Automobile Club de l’Ouest and co-Chair of Mission H24, Pierre Fillon points out that this project was launched a few years ago: “From 2018, our aim was to demonstrate, step by step, that hydrogen technology wasn’t just science-fiction, but a genuine, efficient, promising solution and above all the guarantee of zero-emission mobility and racing”.

Michelin, through its Symbio subsidiary, and Total are partners in this project. Beyond developing technology and a car, Mission H24 aims “to help create a new hydrogen-powered class for the Le Mans 24 Hours in 2025”. In the context of these burgeoning rules and regulations, GreenGT has developed a new type of car “Le Mans Prototype” LMP, equipped with a high-power Symbio fuel cell. This car has been entrusted to a racing team whose mission is to perfect its development and take part in Michelin Le Mans Cup racing weekends”.

First warm-up laps

The H24 car has the latest generation fuel cell, with new bipolar plates developed by Symbio. Presented at the Le Mans 24 Hours in 2020, the Mission H24 demonstration vehicle LMPH2G drove round the track before the start of the race. Its driver was Carlos Tavares, Executive Director of Stellantis (previously PSA) and motorsport enthusiast. A promising start and proof that the hydrogen-powered race car is not just a dream, but a reality!

In 2025, a hydrogen-powered electric car will run in the Le Mans 24 Hours. For its hundredth anniversary, this legendary motorsport event will begin a new chapter in its history.

Zero Emission Valley

Fully aware of what is at stake in clean energy and with a high concentration of “hydrogen sector players” in its area, the Auvergne-Rhône-Alpes region decided to launch the “Zero Emission Valley » project. Michelin and Engie are also partners in this promising adventure.“Zero Emission Valley”: Auvergne-Rhône-Alpes wants to become the leading hydrogen region in the EU

Fully aware of what is at stake in clean energy and with a high concentration of “hydrogen sector players” in its area, the Auvergne-Rhône-Alpes region decided to launch the “Zero Emission Valley” project. Michelin and Engie are also partners in this promising adventure.

The Auvergne-Rhône-Alpes region wants to develop hydrogen mobility in its territory. Between now and 2023, thanks to the ZEV project, 20 “green” hydrogen charging stations will be set up, using hydrogen produced from renewable energy sources. Laurent Wauquiez, Regional President explains: “Environmental conservation is without a doubt the challenge of the 21st century. Auvergne-Rhône-Alpes is home to most of the major players in the hydrogen sector. This is exactly why the region has invested so strongly in favour of hydrogen with the Zero Emission Valley project. This will allow us to make Auvergne-Rhône-Alpes one of the most carbon-neutral areas in the EU as we federate all those involved in the sector to reinforce clean energy development. In parallel, we’ll be helping to develop an ecological transition capable of generating sustainable growth and creating jobs”.

A project supported by ADEME* and by the EU

*French Energy Transition Agency

This initiative, among the most significant in the EU, is at a regional level and encourages both installation of hydrogen charging stations and the launch of vehicles. It mostly concerns large metropolitan areas which, along with implementing charging stations, have committed to finding purchasers for around fifty hydrogen-powered light commercial utility vehicles.

Backed by the EU, with financial support of 10.1 million euros, the aim of the project is to launch the market by simultaneously rolling out a network of 20 special charging stations and a fleet of 1,200 vehicles between now and 2023. The 14 million euros support from the ADEME will principally fund the purchase of small vans and buses. Thanks to the cumulation of European, national and regional funding, support for the purchase of hydrogen vehicles could reach 15,000 euros – on condition that the vehicle covers over 25,000 kilometers a year.

A distinctive feature of this project is that the Auvergne-Rhône-Alpes region and its partners

Michelin, Engie, Crédit Agricole and the Banque des Territoires, have created a trading company, called Hympulsion, to build and run the hydrogen charging stations.

A regional hydrogen subsidiary

The first of the twenty planned stations has been in place since February 2020 in Chambéry. The network will mainly concern major conurbations in the area, but also smaller communities such as Riom, Moûtiers and Modane. Note that a provisional hydrogen charging station has been set up by Michelin in Clermont-Ferrand while waiting for the final station planned for 2022. These stations will be built by the Atawey-HRS-McPhy group who will also supply the system for hydrogen produced by water electrolysis.

The region’s hydrogen vision goes beyond traditional road vehicles – cars, utility vehicles, coaches and buses. It extends to bikes, trains, boats and even snow groomers! For the latter, regional authorities have begun discussions specifically with the Compagnie des Alpes. Lastly, a hydrogen usage strategy would not be complete without a plan for electricity storage, to be released during consumption peaks.

Beyond this type of use, installation of the Symbio plant in Vénissieux completes an industrial set up that also covers Michelin activities in Clermont-Ferrand, and those of the Atomic Energy Commission and Alternative Energy Commission (CEA) research laboratories in Grenoble.

Through all these actions, Auvergne-Rhône-Alpes confirms its ambition to become the leading hydrogen mobility region in the EU.

Michelin uses green hydrogen in Vannes

In the context of its Hygo project, Engie Solutions and Morbihan Energies are producing green hydrogen in Vannes, green meaning from carbon-neutral bio-sources. This EffiH2 project meets two objectives: to produce green hydrogen through electrolysis and to supply a public hydrogen charging station for vehicles. It therefore allows two end uses: fueling both the Michelin plant in Vannes and vehicles too.

The station was built near the Michelin plant in Vannes, in the Prat Industrial Zone and was put into operational use at the end of 2020. Engie Solutions and Morbihan Energies have invested 4.6 million euros in this project. The latter receives financial support from the ADEME in the context of a call for Eco-mobility hydrogen projects, to the sum of 780,000 euros. Furthermore, the ADEME will accompany purchasers of hydrogen vehicles who use this refueling station with an overall budget of 990,000 euros.

Act against air pollution, right here, right now!

Act against air pollution, right here, right now

Mathieu Gardies

Why is air pollution a matter of urgency?

I was born in 1971. People of my generation remember that some of our perfectly loving and responsible parents also smoked with children in the car. Most of these cars also gave off dark billows of smoke so, as children, we played at comparing the smells.

So yes, without a doubt air pollution has dropped quite significantly in recent decades. However, unlike our parents, we now know the physical impact of this scourge: 97 000 deaths in France and 8 million throughout the world in 2018, according to the latest study released early 2021. That’s just for fossil fuels and doesn’t take into consideration the impact on our children.

How to meet this challenge?

With this in mind, the time for debates between experts needs to give way to a rapid roll out of practical solutions.

It’s a matter of fact that, contrary to greenhouse gas emissions, air pollution can be reduced quickly and locally. Which doesn’t mean to say that we’re pushing the problem despondently towards our neighbors but that the effects it produces are more or less dangerous depending on where it’s produced. We instinctively understand, and it’s effectively the case, that a cigarette or car exhaust less than one meter from a pushchair in a busy Parisian street is more harmful than the same emissions in unpopulated areas.

A significant amount of harmful fine particles comes from conventional vehicles and we now know that successive European norms will not solve this problem. Consequently, in these densely populated urban zones we should limit traffic congestion and, where possible, the use of passenger cars by continuing to back the emergence of sustainable mobility modes for all types of use. But also aim for zero-emissions directly at exhaust level, hence the electric engine, for all remaining passenger vehicles. This would already help to bring air pollution down to significantly safer levels in many areas.

Why taxis, why hydrogen, and why for all of us?

Taxis, along with buses, tramways, bikes, tramways, delivery services, scooters and car sharing will be part of tomorrow’s cityscapes. They are and will remain a public service. That’s why we need to put solutions in place that will allow them to continue their activities in acceptable conditions, and to stop polluting the next time they renew a vehicle.

The battery electric car does not sufficiently meet the needs of some drivers in Paris and other cities. We can no longer wait for the next generation of batteries, the next network of charging stations, the next power recharging norms, before we take action.

Hydrogen-powered electric vehicles are already effective for these usage needs and situations. Let’s really roll them out, even if there’s still room for improvement with their energy performance, even if all the hydrogen is not yet green. Let’s not procrastinate behind technological solutions, or a list of more pressing emergencies to excuse our inertia.

Entrepreneurs will continue to innovate and take risks, industrialists and financiers will accompany them in an attempt to roll out real solutions on the right scale. Political leaders must continue to support this growth and, when the moment is right, to assume responsibility by enforcing these solutions. It is also up to each and every one of us, as customers, to show drivers, through our choices and actions, that we encourage and support them in the move towards zero-emission transition.

Developing innovative hydrogen-mobility solutions for professionals: the Stellantis perspective.

The fuel cell is an efficient solution for professionals. Stellantis already offer « Fuel Cell » vans whose wide scale roll-out will depend on the development of a hydrogen station network. For Stellantis top management, hydrogen makes it possible to satisfy customer expectations by covering usage needs inaccessible to battery-electric vehicles. Here’s why.

Innovative technical choices

Carla Gohin, former Stellantis Vice-President Research and Innovation: The Stellantis vision is to offer our customers broad freedom of movement by providing efficient, affordable and sustainable technical solutions. Our hydrogen-mobility solution aims to complete our battery-electric light commercial vehicle range. It’s because we believe that the technologies suggested by Symbio and Faurecia are the right ones that we’ve committed to a partnership with them.

Frank Jordan, Director of Advanced Development at Stellantis Germany: We’ve chosen a solution called « mid-power ». This relies on two energy sources, electricity from the battery on the one hand, electricity from the fuel cell on the other, and enables both elements to function optimally. What we need is a reduced-size battery, located under the hood and above the electric engine. This gives increased range and a very short recharging time. These batteries will be stored under the front passenger seats, with the hydrogen tanks in the floor.

For highly demanding professionals

Xavier Peugeot, Director Light Commercial Vehicles Business Unit at Stellantis: We’ve made no concessions to performance, either in terms of effective volume or loading volume. This offer of medium-size commercial vehicles, Peugeot Expert, Citroën Jumpy and Opel Vivaro, already comes in an electric battery version. It covers a wide scope of use, for 83 % of our customers do less than 200 kilometers a day. On the other hand, some make much longer daily trips. With a range of 400 kilometers, these hydrogen-powered electric commercial vehicles cover numerous types of use.

The ability to overcome challenges

Dominique Sadoul, Director Advanced Development, Engines and Energy: The « mid power » solution developed with Symbio provides just the right balance between performance, profit and cost. But challenges remain before fuel-cell mobility reaches its full potential. In particular the capacity to access low cost green hydrogen, a sufficient number of special hydrogen stations and a competitive overall usage cost.

Opening up new fields of possibility

Carla Gohin: hydrogen enables us to satisfy customer needs by covering types of use inaccessible to battery-electric vehicles. What’s more, the recharge time of just a few minutes is a key point for professionals. We are pioneers with this fuel cell technology, primarily intended for utility vehicles. The next phase will be rolling out the experience acquired to passenger cars.

Xavier Peugeot: We are targeting customers with more demanding usage needs than those covered by existing battery-fueled utility vehicles. They need a vehicle that makes no concessions on performance and they will have it. This type of mobility will be available for Peugeot, Citroën and Opel commercial vehicles in two lengths, medium and high.

Behind the “Businova H2”, the challenge of reindustrializing and developing the hydrogen sector

Equipping a bus with a fuel cell? Obvious from the start of the project, thanks to technology developed by Symbio, a Michelin-Faurecia joint venture.

SAFRA has been working on the Businova project for over 10 years. This is both long and short considering it involves a truly innovative industrial project. Even counting on historic expertise, sound knowledge of markets, organizing operators and authorities, plus a good understanding of major trends in the city of tomorrow and sustainable mobility.

From the start of the project, we wanted to develop a bus that ran on hydrogen. Foreward-thinking and adventurous, we kicked off with a hybrid solution, followed by an “all battery” solution, before finally turning to a hydrogen-powered zero-emission solution in 2018. We believe in this energy solution for passenger transport and in its potential for reindustrialization in Europe.

In April 2021, twelve “Businova H2” buses were operating in France. Six in Artois-Gohelle, five in Versailles and one in Le Mans. The Auxerre urban district has took delivery of the first of the five vehicles it has ordered. Five “Businova H2” buses are also planned for the Hyport in Toulouse. We also have an order for three 100% battery-run Businova, planned for the Marseille public transport network.

An approach consistent with a hydrogen ecosystem and carbon-neutral transport

Today, as we clearly see that the hydrogen sector is in full swing, our product arrives at a timely moment. With the “Businova H2”, we’re aligned with all the political leaders which is quite something given that Europe, along with the state, regions, localities and cities are all currently developing ambitious hydrogen policies.

The vast French Recovery Plan with its 7 billion euros budget has given a new lease of life to an industry ready to prove the relevance of hydrogen for our country, both for the environment and the economy. Leading French industrialists are working together to relocate the energy industry and decarbonize the economy, with the support of the National Hydrogen Council, whose first meeting was held at the SAFRA offices in Albi, in the presence of three ministers.

The challenge of reindustrialisation

In France, political leaders are interested in our “Businova H2” product. Yet it is the potential for reindustrialization on a European scale that really grabs their attention, along with the creation of hundreds of new jobs in this sector. We are proud to be part of this industry and to offer a product designed and made in France, the only hydrogen bus on the market with a European fuel cell, also made in France by Symbio.

Available content